Butter

Pre-assesment

Butter

Butter is an energetically and nutritionally highly valuable dairy product, which is obtained by processing sweet or fermented (sour) cream, by the process of churning. During the process of churning, the fat globules unite and first smaller and then larger butter grains are formed, and buttermilk is separated. Butter is generally a concentrated milk fat and contains a minimum of 82% milk fat.

Whey butter made from cream obtained by whey separation can also be found on the market, as well as butter with additives.

Butter production has been known since ancient times. Butter was originally made on farms for domestic use. The milk fat separated naturally, as a surface layer of milk, and then it was removed and left to ripe naturally, and then it was churned. The churning was done in wooden manual churns. The traditional way of butter production is unacceptable today due to poor hygienic conditions that can result in poor quality and health safety of the finished product.

Figure 1. Manual churns for butter-making

The invention of the separator (1878) enabled the fast and efficient skimming of cream from milk, which enabled a great leap in the butter production, and the quality and economy of production were further increased by the introduction of the pasteurization process (1880). Modern butter production, with the application of controlled acidification, has resulted in a significant improvement in product quality.

Legal regulation

The Rulebook on the quality of milk products and starter cultures (2014) defines the requirements that butter must meet:

- To have a characteristic aroma, taste and colour;

- To have an easily spread, homogenous consistency without visible water droplets;

- To contain not less than 82% of milk fat;

- To contain no more than 16% of water, and

- To contain no more than 2% of dry matter of fat-free milk.

As well as the requirements that whey butter must meet:

- To have a characteristic smell, taste and colour;

- To have an easily spread, homogenous consistency without visible water droplets;

- To contain not less than 80% of milk fat;

- To contain no more than 18% of water, and

- To contain no more than 2% of dry matter of fat-free milk.

PDF document

PDF documentTECHNOLOGICAL PROCESS OF BUTTER-MAKING

The butter-making process includes the following stages

- Cream production – includes the process of milk skimming and standardization of milk fat content in cream

- Cream processing – means cream pasteurization, and then its physical and biochemical maturation – if butter is produced from fermented cream

- Processing of cream into butter – this is the process of churning when a butter grain is formed with the separation of buttermilk.

- Butter packaging, storage and distribution.

Butter can be produced by a batch and continuous process. The batch process is older and, in this process, butter can be produced from sweet and sour cream, and is usually applied in smaller dairies where there is also a smaller amount of cream. The continuous process of butter production is of a more recent date and it uses mainly sweet cream, and is used for the production of butter in larger dairies.

Figure 2. General process steps in batch and continuous production of cultured butter (Dairy Processing Handbook ©Tetra Pak)

- Milk reception

- Preheating and pasteurization of skim milk

- Fat separation

- Cream pasteurization

- Vacuum deaeration, when used

- Culture preparation, when used

- Cream ripening and souring, when used

- Temperature treatment

- Churning/working, batch

- Churning/working, continuous

- Buttermilk collection

- Butter silo with screw conveyor

- Packaging machines

CREAM PRODUCTION

Cream is an emulsion in which milk fat globules float in the water phase so-called cream serum. It is obtained by separating milk fat with a centrifugal separator or separating milk fat on the surface of milk during milk standing. The separation is performed at a milk temperature between 50 and 60°C, at that temperature all the milk fat is in liquid form, which is important for the success of the separation. After the separation, cream is standardized, usually up to 40% milk fat (by adding skimmed milk if the milk fat content is high, or by adding higher fat cream if the milk fat content is low).

To obtain quality butter, it is very important to choose cream of good microbiological quality, with taste and aromas.

CREAM PROCESSING

Before churning, it is necessary to pasteurize the cream, and then cool it to the ripening temperature.

Cream pasteurization

When processing the cream, care should be taken that cream for butter production is not homogenized. The cream is pasteurized at a temperature of 85-95°C, for 10 to 30 seconds. The goal of pasteurization is to destroy microorganisms, primarily pathogens, as well as their enzymes, and lipase inactivation is especially important.

Cream pasteurization shortens the churning time, which is a direct consequence of the changes that occur in milk fat and whey proteins.

Cream ripening

The cream ripening is a very important stage in the process of butter production. The taste and aroma depend on this phase, but also the consistency of the butter.

In cream ripening there are:

- biochemical and

- physical ripening

Biochemical cream ripening

Biochemical cream ripening is a process of fermentation of cream using mesophilic dairy cultures, the use of which produces sour/fermented cream. Mesophilic culture consists of selected strains of Lactococcus and Leuconostoc bacteria, which ferment lactose to lactic acid, but also produce citrates and aromatic substances – diacetyl and volatile acids. Biochemical ripening takes place at a temperature of 18-22°C, 12 to 20 hours, until the pH is lowered to 4.6. It is interrupted by lowering the temperature to below 10°C.

Physical cream ripening

Physical cream ripening implies physical changes in the structure of milk fat. Mandatory process in the production of butter from both sour and sweet cream, which comes before the churning. It takes place in duplicators at low temperatures, 10 – 12°C, lasting a maximum of 15 hours. The goal is to harden and crystallize the milk fat globules, which become more suitable for destabilization. There are also changes in the proteins attached to the membrane of the fat globule, which bursts more easily later in the process of churning.

The length of cooling depends on the composition of the fat, which depends on the season, i.e., the diet of the cows. In the summer months, when “green food – grazing” is present, milk fat contains fewer fatty acids with a lower melting point, and there is a high content of oleic acid, which results in a high iodine number and soft butter. The iodine number represents the number of g of iodine required to saturate unsaturated fatty acids in 100 g of fat and is an indicator of the proportion of unsaturated fatty acids. The optimal consistency of butter when the iodine number is 32 – 37. Due to all the above, the physical ripening of butter, at the same temperature, lasts longer in summer than in winter.

CREAM CHURNING

Cream churning is a process of agglomeration of fat globules, due to mechanical cream processing (which is an emulsion of fat in water) into butter (which is an emulsion of water in fat). In milk and cream, fat globules do not stick together because they are protected by a membrane. During the churning process, due to the rupture of the membrane of the fat globule, piles of fat globules are created, which are collected and connected into the butter grain. After the churning is completed, the buttermilk is released, which is a by-product in the butter production. Buttermilk contains about 8 – 8.5% dry matter, 0.3% fat, 3.3% protein, 3 – 3.6% lactose, 0.78% mineral matter and 0.1-0.12% lecithin.

BUTTER GRAIN RINSING

After releasing the buttermilk, the butter grain is washed with water, 2-3 times, but this is not an obligatory operation. The rinsing water must be bacteriologically and chemically correct, with the temperature that is by 1°C lower than the temperature of the butter. By rinsing, the remaining buttermilk is separated from the butter, i.e., proteins and lactose, in this way the shelf-life of the butter is extended, because the substances necessary for the growth and development of microorganisms are removed.

BUTTER WORKING AND SALTING

Working

The butter is worked to a homogeneous mass to regulate the amount of water in the butter. The working of the butter is done to obtain a homogeneous mass of butter, in order to obtain the smallest possible droplets of the aqueous phase, evenly distributed in the butter.

Salting

Salt can be added to the butter after rinsing, and before working. About 1.2 to 1.5% of salt is added in summer and 0.8 – 1% in winter. It gives taste and prolongs the shelf-life of butter.

BUTTER PACKAGING AND STORAGE

Butter is packed in packages (aluminium foil, paper, …) from 0.1 to 1 kg. Larger quantities of butter are packed in larger boxes of about 25 kg. When packaging, it is very important to avoid contact of the butter with air or light in order to avoid unwanted changes.

Butter is stored at temperatures of 4 – 5°C for a month. It can be frozen, so its shelf-life is significantly extended.

BATCH BUTTER-MAKING

Butter is produced by a batch process in churners. The churners are filled with cream up to 45% of the volume, because a lot of froth is created during the churning. The churning takes place at a temperature of 10-15°C (in summer at 8° -10°C, and in winter at 11° -14°C). The churner rotates at a speed of 20 to 30 rpm, during mechanical shocks the membrane of the fat globules cracks and butter grain is formed. The cream temperature rises to 2°C during the churning process. Churning lasts 35-45 minutes, and depending on the content of milk fat in the cream, the optimal content is 28-36%. Once the size of the butter grain gets 2 to 3 mm in diameter, the churning is finished. The length of the churning is also affected by the temperature, at higher temperatures it takes less time, but there is a higher percentage of milk fat in the buttermilk. After the churning is completed, the buttermilk is drained, the butter is washed and worked, and then it is packed and stored.

Figure 3. Low-capacity churner for small dairies

Figure 4. Churner

CONTINUOUS BUTTER-MAKING

The continuous butter-making process occurred as a consequence of efforts to shorten the duration of the butter-making process, reduce labour and energy costs. There are three different processes, and in Western Europe the most common is the Fritz process, developed from the batch butter-making process.

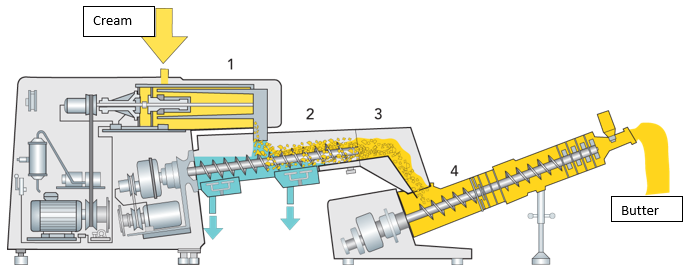

The cream from the ripening tank enters the first cylinder (1), which rotates at a speed of 2000 rpm, where a butter grain is formed, and in the second (2), which rotates 35 rpm, the buttermilk is separated. It then passes to the squeeze-drying section (3), in which the excess buttermilk is separated, and then to the second working section (4). The butter comes out in the form of a ribbon that is directed towards the moulding and packaging device.

Figure 5. A continuous butter-making machine (Dairy Processing Handbook ©Tetra Pak)

- Churning cylinder

- Separation section

- Squeeze-drying section

- Second working section

PRODUCTS SIMILAR TO BUTTER

Milk fat, from which water, proteins, lactose and other milk ingredients have been almost completely removed, is used in different parts of the world under different names, and different technologies are used in the production process.

In Serbia, this product is called maslo, in India ghee, in Arabia and Egypt samn, and in some eastern countries mislee. In European countries, the following names are used: butterfat, melted butter, liquid butter, etc., while in the USA it is called butter oil, and in Australia and New Zealand dry butterfat.

The use of dehydrated milk fat is especially present in warm tropical regions, with high temperatures, where the shelf-life of butter is reduced due to the faster development of microorganisms in the aqueous phase.

Butterfat

Butterfat is a dairy product with a high content of milk fat that is produced by melting butter or melting butter and cream. The butterfat is golden yellow in colour, with a pleasant taste and aroma.

Quality butterfat, in addition to a minimum of 98% milk fat, contains up to 1% water and up to 1% other ingredients. Shelf-life of butterfat with these characteristics can last longer.

The butterfat was mainly used in the household in which it was produced. It is popular in the diet of people from hot regions and people who do not use lard in their diet. Compared to butter, it is more stable at room temperature. It is suitable for reconstitution, both in obtaining milk from skimmed milk, and in the production of ice cream and chocolate milk.

Butterfat making

Most often, butterfat is produced by heating butter in a boiler/vessel to which a little water was added beforehand. While heating, the resulting foam is removed from the surface of the melted butter, and once the mass acquires a specific colour, the heating stops. The resulting butterfat is left to gradually cool and during cooling the precipitate, which consists of nitrogenous substances, lactose and minerals, falls to the bottom of the vessel. Once the temperature of the butterfat drops to about 35°C, it is poured, if necessary filtered, into clean containers and cooled at low temperatures.

In addition to the production of butterfat from butter, it can also be made from cream, when the churning process is avoided. Before heat treatment, it is necessary to break down the fat globules mechanically, in order to separate the fat.

The butterfat can be stored for up to a year at a temperature of 4°C.

GHEE

Ghee is a butterfat produced in India mostly from buffalo milk, which has a higher milk fat concentration (7.5%) and larger fat globule, compared to cow’s milk. It is obtained by sour cream churning and then melting the produced butter.

Ghee has a characteristic taste and smell that comes from the fermentation of the cream, and it also has a high concentration of free fatty acids. It is often darker in colour than butterfat, if the heating temperature exceeds 130°C. The structure depends on the method of cooling, with rapid cooling with stirring, a fine-grained structure is obtained, while with gradual cooling at room temperature without mixing, larger fat crystals are obtained.

ANHYDROUS MILK FAT – AM

A product that is concentrated milk fat and contains a minimum of 99.8% milk fat. It is made from cream or butter.

AMF is in the liquid phase at temperatures above 36°C and in the solid phase below 16°C.

AMF is an excellent form for storing and transporting fat, because it requires less space than butter and can be stored longer than butter (at a temperature of + 4°C butter can be stored for up to 6 weeks, and butterfat packed with inert gas may last for a few months).

AMF is suitable for use in the liquid phase. It is used in the industry for the production of chocolate and ice cream.

There are three different types of products, which are defined by FIL IDF International Standard 68A: 1977.

- Anhydrous milk fat – must contain at least 99.8% milk fat and is made from fresh cream or butter. The use of any additives is not allowed.

- Anhydrous butter oil – must contain at least 99.8% milk fat and is made from cream or butter of different maturation.

- Butter oil – must contain 99.3% milk fat, produced from cream or butter.

PDF document

PDF documentBUTTERMILK

Buttermilk is a by-product obtained in the butter-making. Buttermilk has a high concentration of fat globule membrane components, and therefore a high concentration of lecithin, about 0.5% milk fat. The shelf-life of buttermilk is very short due to the oxidation of the ingredients that make up the membrane. In the case of buttermilk obtained from fermented cream, whey is often separated.

The composition of buttermilk depends on the butter-making method. Table 1 shows the composition of buttermilk obtained after the butter-making from fermented and sweet cream.

Table 1. Chemical composition of buttermilk

| Composition (%) | Buttermilk from fermented cream | Buttermilk from sweet cream |

| Water | 91.5 – 92 | 91 |

| Fat | 0.3 | 0.5 |

| Proteins | 3.3 | 3.5 |

| Lactose | 3 – 3.6 | 4.4 |

| Ash | 0.78 | 0.73 |

| Lecithin | 0.1 – 0.12 | |

| Lactic acid | 0.6 – 0.7 | 0.01 |

Fermented buttermilk

In order to extend the shelf-life of buttermilk, fermented buttermilk is produced. Butter culture is most often used for fermentation, and skim milk can be added to improve the aroma and consistency.

The raw material is heat treated at a temperature of 90-95°C for 5 minutes, and the product is then cooled to the optimum temperature for the development of the added starter culture.

PDF document

PDF document

Training Presentation

Training Video

Post-assesment