Milk fat is the most valuable and at the same time the most expensive ingredient in milk. Apart from milk, people tried to use products in their diet that to a greater or lesser extent contain certain milk ingredients. Milk is an emulsion or suspension of milk fat in water containing a number of substances in solution (lactose, minerals, vitamins, …), as well as ingredients in a colloidal state (proteins). Milk fat in milk is found in the form of small globules and has a lower density than other milk ingredients, it is separated on the surface of milk during standing or by a separator. The most common products obtained by concentrating milk fat are: cream, kaymak, butter and ghee.

- Milk fat (920 kg/m3) has a lower density than skimmed milk (1030 kg/m3) and when milk is standing, it is released on the surface. Separation speed depends on:

- The size of fat globules, the separation rate increases with increasing the diameter of the fat globule,

- Differences in the density of skimmed milk and fat, the separation rate increases with increasing difference in density and

- The viscosity of skimmed milk, the separation rate decreases with increasing the viscosity of skimmed milk.

The property of separating milk fat on the surface of milk has been used to separate cream. After milking, the milk was poured into containers that were placed in cold water or left in cold air, and after 12 to 24 hours, the cream was removed from the surface.

This method is slow and impractical for modern industrial production, where milk fat is separated by a separator.

Separators are devices that separate milk fat from milk. By separating the milk, the skimmed milk is separated from the milk fat. The separation is based on the difference in the density of milk fat and skimmed milk, with the application of centrifugal force. The centrifugal force acts much stronger than gravity, so using a separator makes the separation of milk fat much faster.

Types of separators

Separators used in the dairy industry can be classified based on several criteria, and the basic classifications are according to their purpose, construction and power.

- According to the purpose in the dairy industry, there are:

- Separators for skimming and partial purification of milk, whey, etc.

- Clarifiers for milk purification, and

- Bactofuge for removing bacteria from milk.

- According to the construction, there are:

- Open separators, with open milk in-flow and open out-flow of skimmed milk and cream,

- Semi-closed separators, with open milk in-flow and closed out-flow of milk and cream,

- Hermetically sealed separators, where the milk in-flow is hermetically sealed, as well as the out-flow of skimmed milk and cream.

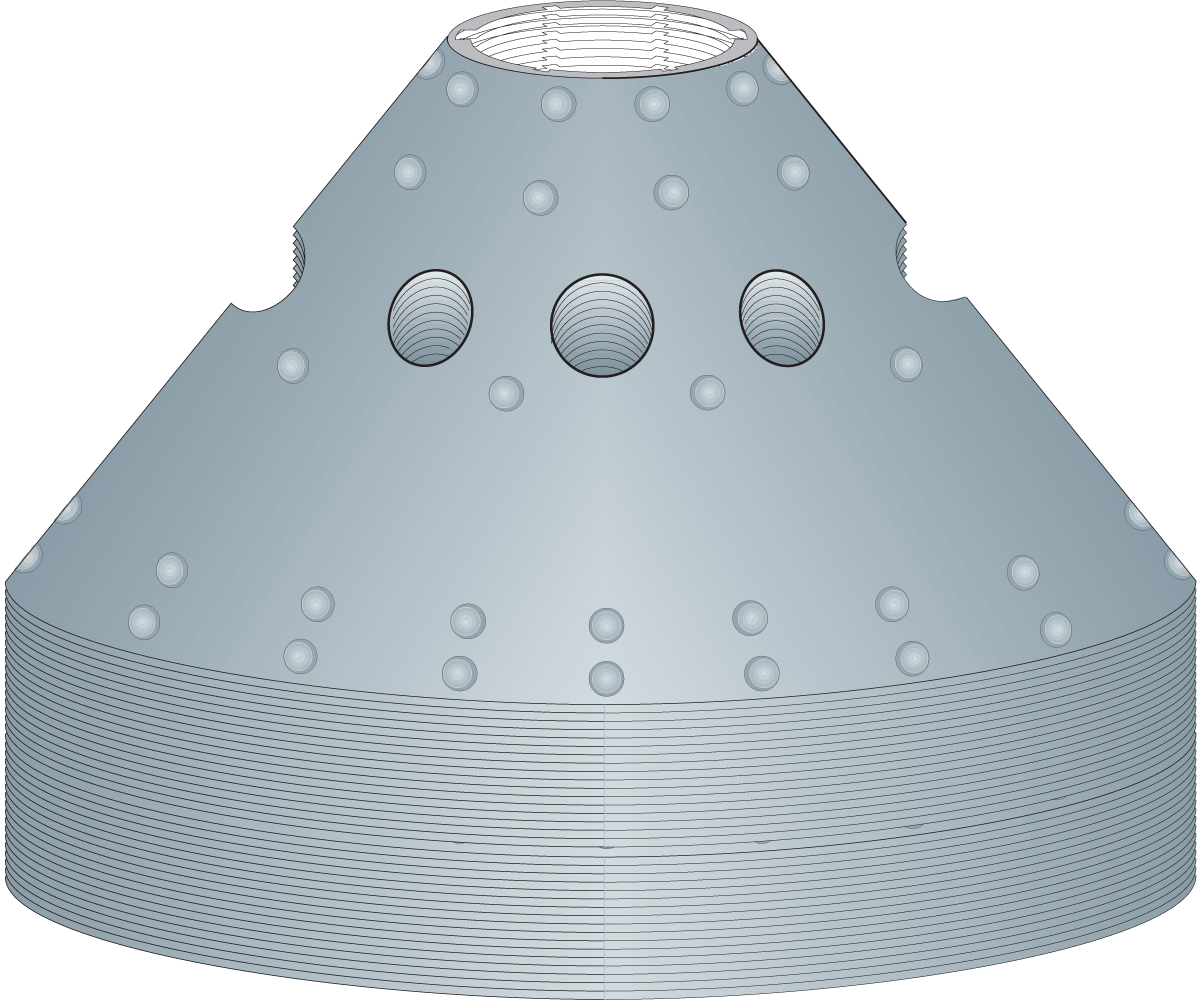

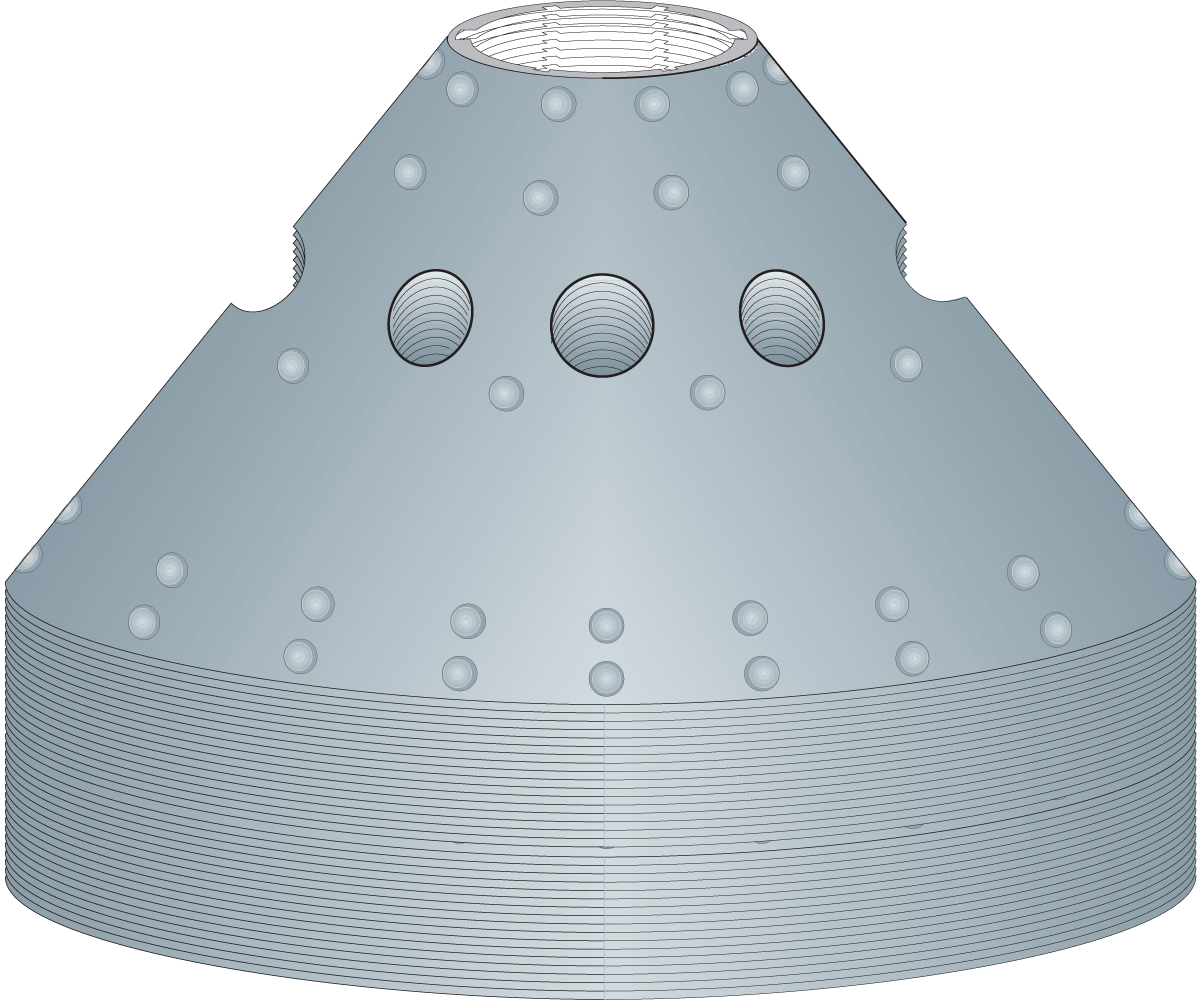

Figure 1. Separators of different construction

Figure 2. Closed, self-cleaning separator

- According to the power:

- Manual

- Mechanical (electric motor, pulley or steam turbine)

- Combined (manual and mechanical).

Figure 3. Manual separator

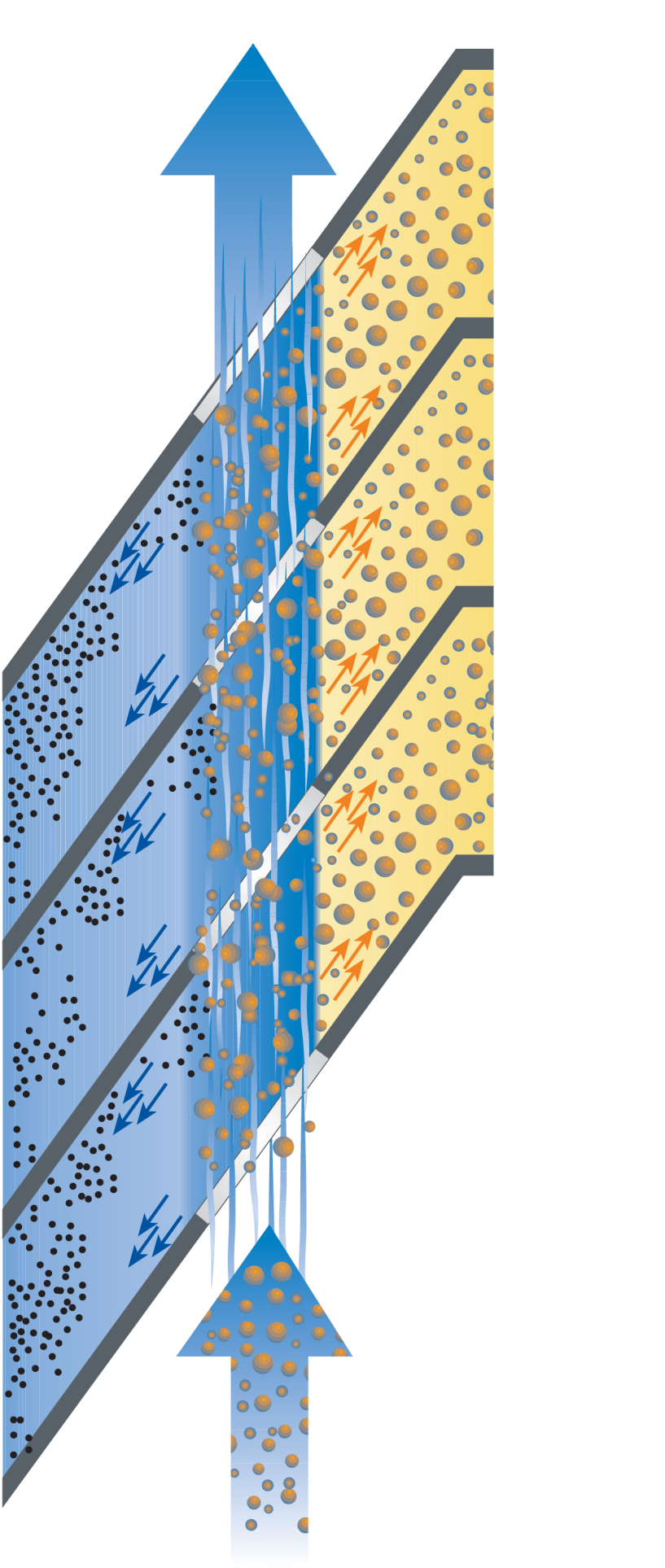

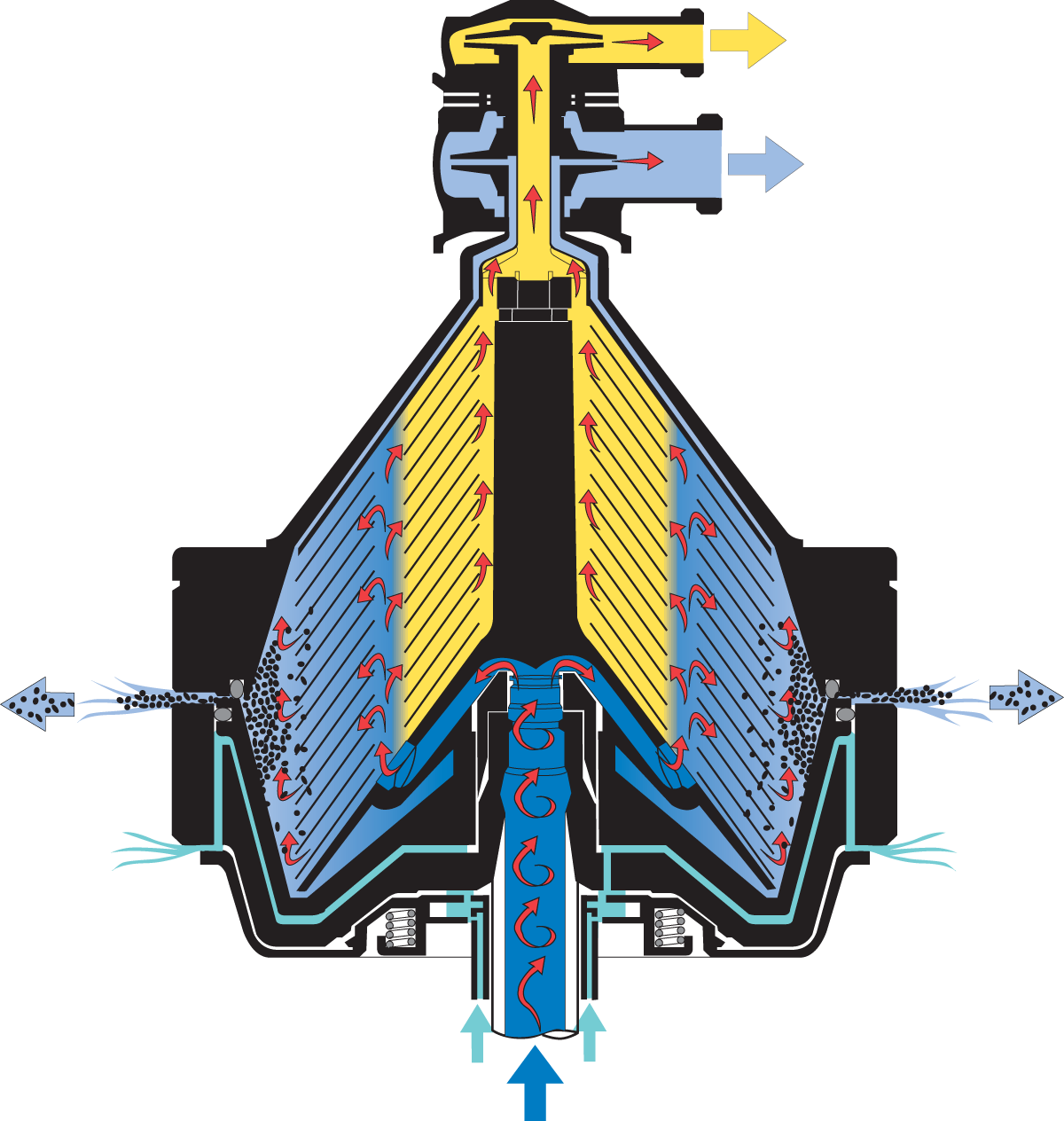

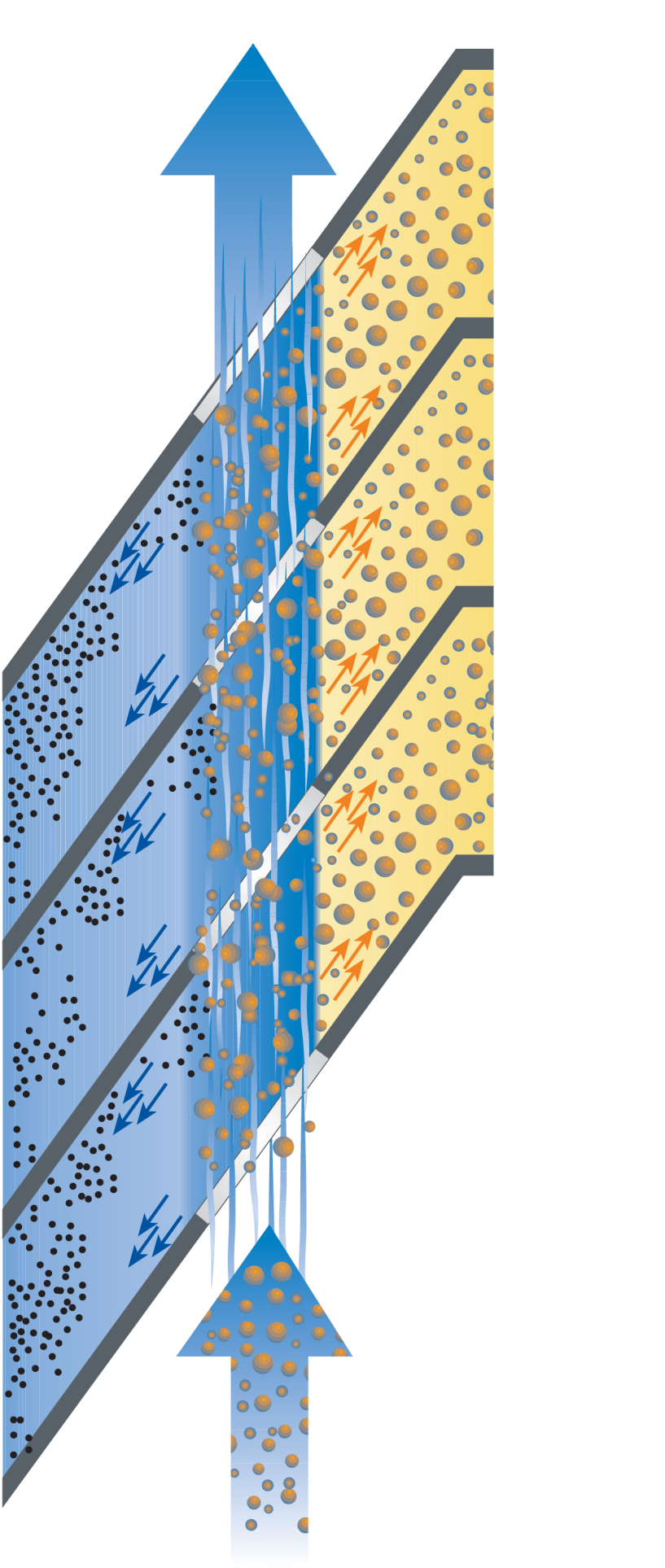

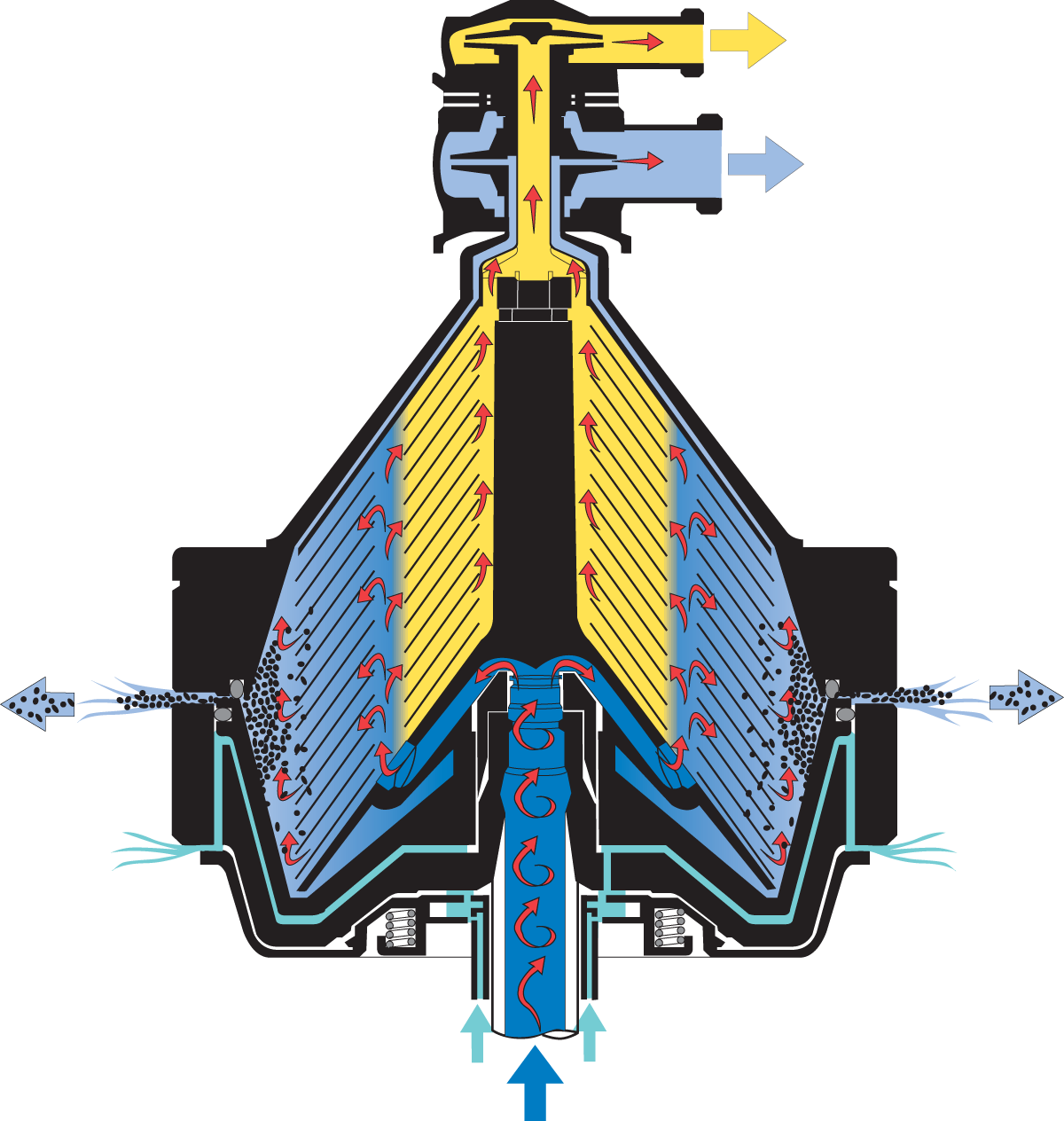

The separator for milk skimming is usually located in the pasteurization line, from where milk, after preheating in the pasteurizer, passes into the separator where the cream is collected. The milk is released into the separator only when it reaches the prescribed number of revolutions (6,000-7,000 rpm). During operation, the separator drum is continuously filled with milk, which is distributed through the openings in layers between the discs during rotation. There are 120 discs in the separator drum, which are placed one above the other, at an angle of 45° (Figure 4). Fat globules, as specifically lighter, move towards the axis of rotation, and skimmed milk, as specifically heavier, moves towards the perimeter of the separator drum. Milk fat is drained in the form of cream through the opening for cream, and skimmed milk through the opening for skimmed milk (Figures 5 and 6). The smallest fat globules do not have time to settle, so they go away together with skimmed milk (about 0.05% milk fat).

Figure 4. Disc stack with distribution holes and caulks (Dairy Processing Handbook ©Tetra Pak)

Figure 5. Schematic representation of how the separator works(Dairy Processing Handbook ©Tetra Pak)

Figure 6. Sectional view of part of the disc stack, showing the milk entering through the distribution holes, and separation of fat globules from the skim milk (Dairy Processing Handbook ©Tetra Pak)

During operation, dirt accumulates in the separator drum, so the separator must be stopped, opened and cleaned. New types of separators so-called self-cleaning separators, remove dirt automatically during operation.

Figure 7. Separation of dirt particles in self-cleaning separators

(Dairy Processing Handbook ©Tetra Pak)

The efficiency of milk skimming is influenced by a number of factors:

- Separator type (diameter and speed of rotation), with the increase of the diameter of the separator, the performance increases, and with the increase of the number of revolutions of the drum, the centrifugal force and the separation of fat from the milk increase.

- Temperature of milk to be skimmed. In industrial milk processing, skimming is most often performed at a temperature of 40-45°C. Cold skimming leaves 0.15 to 0.30% of milk fat in skimmed milk, and skimming at temperatures above 60°C increases the corrosion of the separator, and the viscosity of milk increases due to albumin coagulation and thus reduces the efficiency of skimming.

- Diameter of fat globules. Small globules of milk fat (less than 1×10-6m) move more slowly and are unlikely to separate.

- Product viscosity. As the viscosity of the milk increases, the separation of fat globules decreases, and thus the effect of the separator decreases. Heated milk has a lower viscosity than cold milk, so heating milk improves separation. Also, milk with an increased degree of acidity, i.e., with a lower pH value, due to the increased viscosity, will be less skimmed.

Raw cow’s milk contains an average of 3% to 4.0% of milk fat. In the production of different dairy products, it is necessary to standardize the milk fat content in order to achieve a uniform content in the final product. Standardization of milk fat content is the process of adjusting the milk fat content in milk intended for the production of various dairy products. Standardization can be achieved by using a separator or by mixing skimmed milk and milk/cream. The standardization process yields milk with the required milk fat content.

Strategic planning

Scheme 1. Milk separation and standardisation process (Dairy Processing Handbook ©Tetra Pak)