Sensory analysis

Welcome to the milk-ed project training. Here you will find training about sensory analysis. Please note that you can download the material and don’t forget to do the self assessment at the start and the end of the module

Sensory evaluation of dairy products

Most consumers are interested in the quality of the dairy products they buy, which they usually determine primarily through their senses, i.e. sensory evaluation. This is something that dairy producers should be aware of. It is therefore advisable to sensorically evaluate each batch of dairy products before they reach the market. It is also useful to check the quality of other producers’ dairy products from time to time. Only such a comparison provides a good basis for objectively evaluating the quality of one’s products.

Sensory evaluation is carried out for various purposes. Let us highlight a few of the most important ones:

- to assess the characteristics of finished products,

- to control the quality of the raw materials,

- to design and develop new products,

- to monitor the influence of raw materials and additives on product quality,

- to check the shelf life of products during storage,

- to evaluate competing products.

Training content

Presentation – Sensory evaluation of dairy products

Presentation – Conversion of the quantity of milk products obtained

Presentation – Shelf-life and storage of milk and milk products

Presentation – Tips for making dairy products

Downloads

General on sensory evaluation

Pre-assesment

General on sensory evaluation

Sensory evaluation is the oldest way of checking the quality of dairy products and involves evaluating their characteristics using the five basic senses (sight, smell, taste, touch, and hearing). The properties of foodstuffs that are perceived by the senses are described in terms of the appropriate terms. In sensory evaluation, we focus on each sensory property of the food under investigation in the following sequence:

- visual appearance by sight,

- smell by olfaction,

- consistency by touch,

- sound by hearing,

- taste by flavour.

The correct sequence of evaluation

The correct sequence of evaluation

The first consideration is the appearance of the dairy product, as this is the first information or first impression of the product. The size, shape, colour, surface appearance, etc., are observed and described by the assessors using the appropriate agreed terms specific to each group of dairy products. Some examples to describe a sample of a dairy product:

- size: too large, too small, typical size, still meets the requirements;

- shape: convex, inflated, too low, nicely rounded, deformed;

- colour: characteristic colour, discoloured, streaked, marbled,no-sheen;

- surface appearance: smooth, wrinkled, cracked, damaged cover, mouldy, etc.

This is followed by an evaluation of the odour of the dairy product, which is formed by the volatile substances contained therein. The volatiles are detected by the sensory organs in the nasal cavity. The intensity of the odour depends on the temperature of the sample, as more volatiles are released at higher temperatures. Therefore, when preparing the sample, the temperature range that is normal for the consumption of the dairy product in question must be taken into account. The odour is described by the following terms: characteristic, intense, bland, repulsive, faint, floral, musty, rancid, impure, chemical, burnt, sour, fruity, yeasty, honey-like, etc.

This is followed by the consistency of the dairy product, which is defined by the type of sensory cells, which are most concentrated at the fingertips, but also on the gums, tongue, and palate, which can only be assessed by tasting. The consistency of a dairy product can be described in the following terms: soft, hard, granular, smooth, sticky, floury, pasty, stringy, crumbly, brittle, coarse, oily, etc.

Sound is a characteristic that is not assessed in most dairy products. Exceptions are the wafery quality of ice creams and the crunchiness of various additives such as crispies, nuts, extruded rice, etc. This characteristic is described by the following terms: crunchy, effervescent, crackling, crepitating, not pronounced enough, etc.

Tasting is the final assessment of a dairy product, as we must know for certain that we are looking at a dairy product that is fit to eat, just by using the senses listed above. If in doubt, do not taste the product, as doing so may be dangerous to your health.

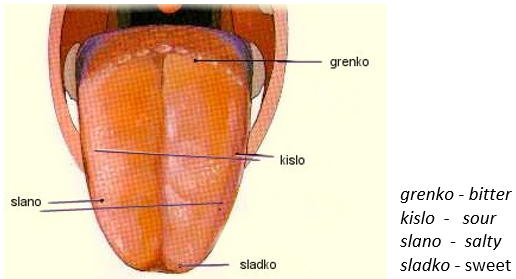

Taste is the most important characteristic of any dairy product and has a decisive influence on sensory evaluation. We perceive the intensity of the following basic tastes: sweet, sour, salty, and bitter, as well as electric, soapy or metallic taste. The sensory organs for each of the basic tastes are located throughout the oral cavity but are concentrated on a specific part of the tongue, as indicated in the following figure.

Common terms used to describe the taste are: sweet, sour, fruity, astringent, rotten, harmonious, spicy, pronounced, yeasty, pungent, loose, zesty, burnt, etc.

Sensory representation in sensory evaluation.

| Feature | SENSE ORGANS | |||||

| eyes | nose | tongue | mouth | fingers, mouth |

ear | |

| appearance | X | |||||

| smell | X | |||||

| taste | X | |||||

| consistency | X | X | X | |||

| sound | X | |||||

Basic conditions for official sensory evaluation

Basic conditions for official sensory evaluation

The sensory evaluation of milk and milk products shall relate only to their sensory characteristics. Objective sensory evaluation and thus reliable assessments of the characteristics of the dairy products concerned can be achieved if the following conditions are ensured:

- a sensory evaluation room

- a sensory evaluation panel,

- the minimum quantities of samples required for sensory evaluation,

- proper storage of the samples,

- properly prepared and labeled samples of dairy products,

- the correct order of the dairy product samples for sensory evaluation,

- the evaluation sheets.

The evaluation of milk and milk products shall be carried out only in suitable premises with appropriate equipment and suitable climatic conditions. A suitably decorated room shall be properly lit, have light cream-coloured walls, a room temperature between 18 and 20 °C, relative humidity of 60 to 70 %, adequate ventilation, be free from foreign or strong odours, and be protected from noise.

The evaluation panel shall be composed of experts or experts with a good knowledge of dairy production who also have experience in sensory evaluation. The assessors shall be qualified to evaluate the sensory characteristics of dairy products objectively and reliably and shall be able to describe them adequately and accurately.

The evaluation panel shall have at least 3 evaluators. One of the assessors shall be designated as chairman of the assessment panel. The assessment panel shall be responsible solely for the professional assessment of the sensory quality of the dairy products by the criteria set out in the assessment sheets. The evaluators shall score to the nearest 0,5 points. If the individual assessors’ assessment of a sensory attribute differs by only one point, either downwards or upwards, the average value determined by the panel shall apply. If the difference between the individual scores is greater, they must repeat the evaluation of that attribute.

Each member of the jury writes his/her mark on the evaluation sheet and signs it. The final marks of all the panel members for each sample are added together and divided by the number of assessors. This gives the average and final score of the milk and milk products samples. A maximum of 50 samples may be assessed per day.

Evaluators shall not smoke, drink coffee or strong alcoholic beverages, or consume food with a sharp taste, 1-2 hours before the start of the evaluation. They shall not use intensive cosmetic products such as toothpaste, mouthwash, deodorant, perfume, aftershave, etc. before the sensory analysis.

The following minimum quantities of samples or number of packaging units are required for the assessment of the sensory characteristics of milk and milk products:

- pasteurised milk: 2 packing units

- fermented milk: 2 packaging units

- sweet/sour cream: 2 packaging units

- kaymak: 2 packing units

- raw/melted butter: 2 packaging units

- cheeses (hard, semi-hard, soft): 1 whole cheese

- fresh cheeses: 2 packing units

The storage conditions for milk and milk product samples pending sensory evaluation are as follows:

- pasteurised and fermented milk, cream, kaymak at a temperature of 4 to 8 °C;

- raw butter at a temperature of 4 to 8 °C;

- fresh cheeses at a temperature of 4 to 8 °C;

- other cheeses at a temperature of 4 to 10 °C;

- other dairy products at the temperature indicated on the declaration.

Most dairy products are assessed at a temperature of between 16 and 18 °C; for fermented milk and milk drinks, a lower temperature of 11 to 13 °C is recommended.

Samples of dairy products shall be properly prepared and labeled by first removing or covering all labels, markings, and declarations from the original packaging from which the assessors could determine the origin or the name of the manufacturer of the product. Only then shall the samples be coded. The code list is inaccessible to the assessors.

The correct order of evaluation means that the evaluators are given the samples with less pronounced and milder flavours to evaluate first, as evaluating spicy products at the beginning of the evaluation would make it difficult, if not impossible, to evaluate dairy products with less pronounced flavours. During the evaluation, the evaluators have water, apple pieces, and white bread to neutralise the taste in the mouth.

For sensory evaluation, the evaluators have the same evaluation sheets that are used in official dairy evaluations in Slovenia. The evaluation sheets are an integral part of the sensory evaluation of the quality of milk and milk products. Each sensory attribute of a dairy product is defined by a certain number of points. Where individual defects are found, the points are deducted. A maximum of 20 points may be scored for a single product.

The sensory attributes of milk and milk products are determined based on the number of points scored. On theBased overall assessment of the sensory characteristics of the product, the products shall be classified in the following quality classes:

| Quality class | Number of points |

| Extra quality class | 20.0 – 19.0 points |

| Quality Class I | 18.9 – 17.0 points |

| Quality Class II | 16.9 – 15.0 points |

However, the following awards may be given to the products examined at the official evaluations:

19.0 to 20.0 points = gold award

18.0 to 18.9 points = silver award

17.0 to 17.9 points = bronze award

For sensory evaluation, we can use the evaluation sheets that are also used in official dairy evaluations in Slovenia. The following are the evaluation criteria and scoring sheets that are also used in official dairy evaluations. In addition, the causes of the most common errors are presented for each group of dairy products.

PASTEURISED MILK

Assessment criteria and scoring grid for PASTEURISED MILK

| Feature | Maximum number of points | Points achieved | Note |

| appearance | 3 | ||

| colour | 2 | ||

| smell | 3 | ||

| taste | 12 | ||

| total | 20 |

| Errors | Causes |

| Elevated acid levels | This is a very common fault, especially in summer. When the acidity level is greatly increased, irreversible (irreversible) damage is done to the milk proteins, which are eviscerated during heat treatment. This defect is caused by lactic acid bacteria and coliform bacteria (Escherichia coli, Enterobacter aerogenes). |

| Sweet curdled | It is caused by the action of micro-organisms that secrete proteolytic enzymes that break down milk proteins. Heat treatment eviscerates the damaged proteins. |

| Rancid-salty milk | This is the result of the action of lipases or the presence of micro-organisms that secrete lipases. |

| Pulling or slimy | Milk is more viscous and ‘pulls at the threads’. This is caused by bacteria forming sheaths or capsules. |

| Abnormally coloured | The bluish colour is due to the action of bacteria in the genus Chromobacter; Reddish discolouration is due to infection by Serratia marcescens |

FERMENTED MILK (fermented milk products): sour milk, yoghurt, Greek yoghurt, kefir without additives

Evaluation criteria and scoring system for FERMENTED MILK (fermented milk products): sour milk, yoghurt, Greek yoghurt, kefir without additives

| Feature | Maximum number of points | Points achieved | Note |

| appearance | 1 | ||

| colour | 1 | ||

| consistency | 4 | ||

| odour | 2 | ||

| taste | 12 | ||

| total | 20 |

Faults of fermented milk (sour milk, yoghurt)

| Errors | Causes |

| whey curdling | too low milk heat treatment temperature milk dry matter content too low ripening temperature too high shaking or violent movement of the yoghurt during incubation and storage |

| acidity rising too slowly | milk faults the presence of inhibiting substances old, inactive cultures cooling during ripening |

| thin, runny consistency | too low heat treatment temperature of the milk ripening temperature too low inactive microbiological cultures milk dry matter content too low |

| grainy, lumpy yoghurt | slow acidification starter culture too low |

| inadequate acidification, harsh, sour, musty, unclean taste |

processing of milk with high initial contamination (inadequate cleaning of milking facilities, milk cooled too slowly, stored for too long, and/or stored at too high temperatures) addition of old and/or inactive microbiological culture prevalence of technologically harmful micro-organisms |

| loose, empty taste | uncharacteristic microbiological culture ripening temperature too low |

| floury, gritty taste | too much milk powder added the added milk powder has not dissolved completely |

| too high acidity | too long ripening time over-ripening and/or storage temperature subsequent souring too long ripening period excessive ripening and/or storage temperature subsequent souring |

| too tender, not acidic enough taste | premature interruption of ripening insufficient acid-forming microbiological culture |

| a hint of yeasty taste, taste | yeast contamination from the air and/or from the surfaces of work equipment due to inadequate cleaning and disinfection of equipment use of contaminated microbiological cultures |

| shelf life too short | microbiological contamination from the air and/or from the surface of work equipment contaminated microbiological culture the cold chain broke in storage storage temperature too high microbiologically contaminated packaging poorly sealed packaging |

GREEK YOGURT

| Errors | Causes |

| whey curdling | too low heat treatment temperature of the milk insufficient draining subsequent acidification during storage |

| acidity rises too slowly | milk defects or presence of inhibiting substances old, inactive cultures, cooling during ripening too short a time for acid formation |

| thin, tough texture | The too low temperature of heat treatment of milk incubation temperature too low insufficient fat in the milk inactive cultures |

| short shelf-life | contamination through utensils, equipment, utensils, air infected cultures broken, cold chain storage at too high a temperature microbiologically contaminated packaging packaging not well sealed |

| inadequate acidification, harsh, sour, musty, unclean taste | milk processing with high initial contamination (inadequate cleaning of milking facilities, milk cooled too slowly, storage for too, long and storage at too high temperatures) old, inactive cultures |

| too high acidity | too long incubation time too long incubation storage temperature too high acidification afterwardspredolg |

| yeasty taste | yeast infestation due to inadequate cleaning and disinfection of equipment use of contaminated cultures secondary contamination from the air |

KEFIR

| Errors | Causes |

| over-fermentation | too many kefir grains added yeast predominance in kefir grains |

| kefir tastes too sour | too many streptococci in kefir grains fermentation should take place at lower temperatures |

| uncharacteristic taste, vinegary, rotten, etc. | contamination with unwanted micro-organisms, moulds, and coliforms important hygiene maintenance and rinsing of kefir grains |

SWEET CREAM

Assessment criteria and scoring grid for SWEET CREAM

| Feature | Maximum number of points | Points achieved | Note |

| appearance | 2 | ||

| consistency | 3 | ||

| colour | 1 | ||

| odour | 2 | ||

| taste | 12 | ||

| total | 20 |

SWEET CREAM

| Errors | Causes |

| inhomogeneous appearance | too high-fat content storage for too long |

| mould on the surface of the product | poorly sealed, contaminated, or damaged packaging |

| a musty and undefined odour and taste | inadequate heat treatment of cream subsequent microbiological contamination of the cream excessive storage temperature of the cream |

| a musty smell and taste of fodder | fodder with unsuitable odour contaminated fodder spoiled silage |

SOUR CREAM

Assessment criteria and scoring grid for SOUR CREAM

| Feature | Maximum number of points | Points achieved | Note |

| appearance | 2 | ||

| consistency | 4 | ||

| colour | 1 | ||

| odour | 3 | ||

| taste | 10 | ||

| total | 20 |

SOUR CREAM

| Errors | Causes |

| inhomogeneous appearance | the fat has separated from the sour milk too long storage |

| too sour taste | improper fermentation of the cream due to excessive addition of microbiological culture too high a temperature and/or too long a duration of fermentation |

| too tender, empty, not sufficiently aromatic odour and taste | slowing down the activity of micro-organisms insufficient acid-forming or flavour-forming microbiological culture fermentation temperature too low fermentation is completed too quickly and the required acidity level of the sour cream is not achieved |

| musty smell and taste of fodder | fodder with unsuitable odour contaminated fodder spoiled silage |

| mouldiness on the surface of the product | poorly sealed, contaminated, and/or damaged packaging |

| musty and undefined smell and taste | inadequate heat treatment of cream subsequent microbiological contamination of sour cream storage temperature of sour cream too high |

KAYMAK

Assessment criteria and scoring grid for KAYMAK

| Feature | Maximum number of points | Points achieved | Note |

| appearance | 2 | ||

| consistency | 3 | ||

| colour | 2 | ||

| odour | 3 | ||

| taste | 10 | ||

| total | 20 |

KAYMAK

| Errors | Causes |

| inhomogeneous appearance | draining for too long insufficiently mixed product |

| too sour taste | intensive lactic acid fermentation insufficiently drained product |

| musty smell and taste of fodder | the cream was not properly heat-treated because the heat treatment was carried out at too low a temperature |

| product | poorly sealed, contaminated, and/or damaged packaging |

| a musty and undefined smell and taste | subsequent microbiological contamination storage temperature too high |

| bitter taste | protein degradation due to subsequent contamination of the product by proteolytic micro-organisms storage temperature too high |

RAW BUTTER

Assessment criteria and scoring grid for RAW BUTTER

| Feature | Maximum number of points | Points achieved | Note |

| appearance | 1 | ||

| consistency | 2 | ||

| colour | 1 | ||

| production | 4 | ||

| odour | 2 | ||

| taste | 10 | ||

| total | 20 |

RAW BUTTER

| Errors | Causes |

| mouldy butter | infection from the environment inadequately sealed packaging |

| malty taste | microbiological infection with Lactococcus lactis spp. lactis biovar maltigene contamination of milk or cream with bacteriophages |

| taste of fodder | inadequate or spoilt fodder |

| yeasty taste | yeast contamination of milk or cream |

| hard and crumbly butter | incorrect preparation of the cream for churning, which depends in particular on the fodder, which influences the composition of the milk fat at different times of the year |

HEATED or COOKED BUTTER (GHEE BUTTER)

Assessment criteria and scoring grid for HEATED or COOKED BUTTER (GHEE BUTTER)

| Feature | Maximum number of points | Points achieved | Note |

| appearance | 2 | ||

| consistency | 4 | ||

| colour | 2 | ||

| odour | 2 | ||

| taste | 10 | ||

| total | 20 |

HEATED or COOKED BUTTER (GHEE BUTTER)

| Errors | Causes |

| sediments | the heated butter has not been well strained holes in the strainer/draining cloth too large |

| a layer of liquid at the bottom of the container | not enough evaporated water |

| burnt taste | overheating temperature |

HARD CHEESE, SEMI-HARD CHEESE, AND SOFT CHEESE

Assessment criteria and scoring grid for HARD CHEESE, SEMI-HARD CHEESE, AND SOFT CHEESE

| Feature | Maximum number of points | Points achieved | Note |

| appearance | 2 | ||

| consistency | 2 | ||

| Cross-section / cheese eyes |

3 | ||

| colour | 1 | ||

| odour | 2 | ||

| taste | 10 | ||

| total | 20 |

Evaluation of the characteristics of the cheeses according to the following criteria in the following order:

- the external appearance of the cheese: the appearance must be typical of the type of cheese being assessed, the cheese must be of the correct dimensions, the rind must be typical of the type of cheese being assessed;

- the colour of the cheese: it must be uniform and characteristic of the type of cheese being assessed;

- consistency: it must correspond to the type of cheese being assessed; it may be described as spreadable, cohesive, compact, elastic;

- cross-section: the cheese eyes are observed to be correctly arranged, of the correct size and shape for the type of cheese ;

- smell of the cheese: the smell is characteristic and clean, without any foreign odours;

- taste: it must be characteristic of the type of cheese, without any foreign flavour, and suitably salty.

Defects in the shape of the cheese: too low, too high, inflated, irregularly shaped, concave, convex, slanted.

Defects in the rind or surface of the cheese: thick, thin, rough, cracked, abnormal, dry, moist, oily, greasy, wrinkled, mottled, mouldy, too much red spread, too little red spread, too little noble mould, damaged coating, mould under the coating or the foil, red spread under the coating or the foil.

Colour defects of the cheese: colourless, two-tone, streaky, mottled, marbled, pale, no sheen.

Cheese consistency defects: hard, firm, lumpy, coarse-grained, crumbly, gritty, chalky, crumbly, chalky, brittle, tough, sticky, elastic, smooth, soft, pasty, spreadable, water-repellent, spongy, layered, uneven, not firm enough, etc.

Defects in the cross-section of the cheese: no eyes, few eyes, many eyes, small eyes, muscular eyes, large eyes, torn eyes, atypical eyes, distorted eyes, too fine eyes, unevenly distributed eyes, cracks in the cross-section, mould on the edges, foreign mould, foreign particles, etc.

Odour defects: unclean, foreign, atypical, loose, soapy, rotten, ammoniacal,

Taste defects: pungent, sweet, sour, bitter, astringent, metallic, chemical, sulphurous, rancid, loose, empty, burnt, musty, yeasty, etc.

| Errors | Causes |

| early inflation of cheese | Infection with coliform bacteria or yeasts |

| late inflation of cheese | Infection with butyric acid bacteria, mainly Clostridium butyricum, Clostridium tyrobutyricum |

| Exterior defects | |

| mouldy cheese | moulds of the genera Penicillium and Aspergillus |

| dark (black) rancid cheese | Monillia nigra and Cladosporium herbarum moulds the yeast Torulopsis spp. |

| white rancid cheese or dry rot | Oospora mould |

| The floury rind of cheese | Penicillium brevicaule mould |

| brown spots and patches on the rind | Aspergillus casei mould |

| yellow rind | |

| Dough defects | |

| chalky, crumbly | milk too acidic for cheese |

| sticky, compacted | The rapid drop in milk temperature in the boiler |

| cracked | Cheese dough too acidic, milk calcium % too low for cheese, infection with butyric acid bacteria (late bloating) |

| bumpy | Inadequate microbiological quality of milk, inadequate occupational hygiene, and consequent contamination of milk with coliform bacteria |

| Odour and taste defects | |

| sour | Over-acidity of cheese dough due to inadequate management of the coagulum treatment process |

| too salty taste | Over-salting |

| bitter | Excessive degradation of protein to amino acids, as a result of too much, added rennet or the presence of proteolytic enzymes |

FRESH CHEESES (CURDS) AND CHEESE SPREADS

Assessment criteria and scoring grid for FRESH CHEESES (CURDS) AND CHEESE SPREADS

| Feature | Maximum number of points | Points achieved | Note |

| appearance | 1 | ||

| consistency | 4 | ||

| colour | 2 | ||

| odour | 3 | ||

| taste | 10 | ||

| total | 20 |

CURD

| Errors | Causes |

| whey separated in packaging | insufficiently drained curd before filling into packaging |

| mould on the surface | microbiological contamination from the air or the surfaces of work equipment poorly sealed, contaminated, and/or damaged packaging |

| overly acid curd | too long lactic acid fermentation fermentation took place at too high a temperature overdose of microbiological culture |

| unflavoured and insufficiently acid curd | poor milk quality, suspected presence of inhibiting substances incorrect choice of microbiological culture insufficient dose of microbiological culture too low a temperature and/or too short a duration of fermentation |

| crumbly curd | too intensive lactic acid fermentation (too high temperature or too long duration) too much rennet added heating of the curd coagulum at too high a temperature draining or pressing the curd for too long |

| bitter curd | inadequate rennet too much rennet added microbiological contamination with proteolytic micro-organisms improper storage at too high a temperature |

| taste of acetic acid (vinegar) | microbiological infection with yeasts and acetic acid bacteria |

MOZZARELLA

| Errors | Causes |

| slimy surface | improperly prepared brine (too low salt concentration) |

| The tough and compact structure of the cheese dough | coagulum acidification too low a temperature of the cheese grains before drawing too low a temperature of the water in which the curd is drawn |

| over-sour cheese dough | too much acid at curdling |

| The torn texture of the pieces | microbiological contamination of raw milk with gas-forming micro-organisms subsequent contamination of the product with yeasts or coliforms |

FRESH and WHITE CHEESE IN BRINE

| Errors | Causes |

| slimy surface | undried surface storing the cheese in a closed container |

| foxed cross-section | unevenly distributed fat or additives |

| cheese not firm enough | too little soluble calcium in milk too large cheese grains inadequate processing of cheese grains insufficient pressing of the cheese under its weight |

| The coarse and crumbly texture of the cheese | excessive coagulation and/or processing temperature of the cheese grains coagulation and/or processing of the cheese grains for too long a period cheese grains are too small too long and/or too intensive pressing of the curd excessive addition of salt |

| too low acidity | too short a ripening period before coagulation milk ripening temperature too low before coagulation insufficient addition of microbiological culture inactive microbiological culture |

| too high acidity | too long a period of ripening of the milk before coagulation too high a ripening temperature of the milk before coagulation too much added microbiological culture too high a cheese pressing temperature |

| finely pitted or torn cheese | infection with coliform micro-organisms |

| unclean taste and the musty smell of the stable | storing raw milk under inappropriate conditions the prevalence of technologically harmful micro-organisms |

Post-assesment

TIPS FOR MAKING DAIRY PRODUCTS

The most effective way to prevent contamination by micro-organisms is to practice good occupational hygiene, which includes our hygiene, the cleanliness of the utensils we use, and the cleanliness of the work areas where we manufacture or store dairy products.

It is advisable to wear disposable protective gloves during the final stages of dairy product manufacture (folding moulded cheeses, channeling, cutting and packaging cheeses, packaging raw butter, folding curds, filling into packaging units, etc.) and to use them if there are rashes, cuts or burns on the hands.

When manually filling and packaging dairy products, it is advisable to wear, in addition to disposable gloves, protective masks for the nose and mouth, especially in the case of colds.

It is also advisable to: learn about the properties of milk and the dairy product you choose; carefully read the instructions for making the milk product you have chosen; prepare the necessary working utensils; start making the dairy product following the steps in the instructions; use a thermometer and a watch.

STORAGE OF MILK AND MILK PRODUCTS

Pre-assesment

Milk and most dairy products are microbiologically sensitive foods, so irregularities in transport and storage, especially deviations from the recommended temperature, can affect their integrity and sensory characteristics. This is something to be particularly aware of during the summer months. When purchasing milk and milk products, use refrigerated bags. Purchased dairy products should be immediately transferred to a refrigerator where they can be stored at a temperature of between 4 and 6 °C. Under these conditions, the products will last until the date printed on the packaging, provided, of course, that they are sealed in their original packaging. After opening, micro-organisms from the air settle in the milk and milk products, which causes them to deteriorate more quickly when opened. Some useful recommendations:

- Make a weekly/monthly consumption plan for a specific dairy product in your household.

- Choose the appropriate size of dairy product packs to use them quickly once opened.

- Do not buy dairy products on sale just because they are cheaper.

- Check the expiry date and look for dairy product packs that will expire later, as you are sure to use up the product in the meantime.

- Check your fridge stocks of dairy products regularly and use the FI-FO (first in – first out) principle, which means use the products with the shortest shelf life first.

- Use clear shrink wrap to protect cheeses and raw butter.

- If you don’t use all of a dairy product, you can transfer it to a smaller container that is reliably clean and provides a good seal.

- Store short-life sterilised milk, labelled DURABLE MILK, at room temperature.

- Clean the refrigerator regularly and remove any ice deposits, which is otherwise automatic in newer appliances.

Post-assesment

CONVERSION OF THE QUANTITY OF MILK PRODUCTS OBTAINED

Pre-assesment

Milk conversion coefficients

The following coefficients are used to convert the quantities of milk products obtained from milk:

1 litre of milk = 1.03 kg of milk;

1 kg of butter = 22.50 litres of milk;

1 kg of cream = 8 to 10 litres of milk (using the calculation: 26,30 kg of milk x % milk fat in cream)/100;

1 kg cheese = 10 kg cow’s milk;

1 kg sheep’s cheese = 6 kg sheep’s milk;

1 kg goat’s cheese = 12 kg goat’s milk;

1 kg curd = 8 kg milk;

1 kg other dairy products (yoghurt, sour milk) = 1 kg milk;

Post-assesment