Milk fat products

Cream

Presentation – Cream

Video – Homemade sour cream

Downloads

Pre-assesment

Of the total milk energy value, milk fat accounts for more than 50%, especially in breeds that produce milk with a higher milk fat content. Milk fat has a high biological value and significantly affects the sensory properties of certain dairy products.

Milk fat is the most valuable ingredient in milk. The high price of milk fat dates back to the period when there was not enough butter on the market, so dairies stimulated the production of milk with a higher milk fat concentration. For years, the selection of cows went in the direction of increasing milk production and increasing the content of milk fat.

From ancient times, man has tried to produce dairy products that have a higher content of certain milk ingredients. There are several products on the market that were created by concentrating milk fat: cream and cream products, kaymak, butter and butterfat.

Cream is a product that contains all the milk ingredients, but with a higher content of milk fat, while butter and butterfat are products that contain the largest percentage of milk fat, and the starting material in their production is cream.

The cream quality depends on the physical and chemical properties of milk fat, i.e., on the properties of fat globules that are sensitive to the inappropriate “regime” during the production and processing of milk. For good quality cream, it is important that the fat is in the form of fat globules. A large number of factors affect the stability of the membrane of the fat globules, primarily nutrition, fat composition, thermal and mechanical load …. Adverse conditions, such as poor pumps, transport, storage, … lead to damage to the membrane of fat globules and separation of free fats. The separated fat creates aggregates that adversely affect the separation of milk fat from milk. The existing lipase enzymes act on free fats and lead to the release of free fatty acids, which further lead to a change in the taste and aroma of the product.

CREAM SEPARATION

When milk is still, a spontaneous separation of cream occurs on the surface, due to the difference in the specific gravity of individual milk ingredients, milk fat is separated on the surface of milk as the ingredient with the lowest specific gravity. This method, spontaneous separation of cream, is used in the separation and production of sour cream in the household, but as a slow process, it often cannot meet the hygienic requirements in industrial production. Extraction/separation of cream is done faster with the help of specially constructed devices – separators. The separation of cream and skimmed milk using a separator is based on the difference in density, but the process itself is accelerated by the use of centrifugal force (see more in the section Separation of milk fat).

LEGAL REGULATION

The cream quality in Serbia is regulated by the Rulebook on the quality of dairy products and starter cultures (Official Gazette of RS, 33/2010, 69/2010, 43/2013 – other rulebook and 34/2014). According to the Rulebook, cream is produced by separating fat from cow’s, sheep’s, goat’s or buffalo’s milk and must be thermally processed. Common to all products of this group is that they contain at least 10% milk fat.

According to the Rulebook on the quality of milk products and starter cultures, all products of this group can be placed on the market as:

- heat-treated cream: pasteurized and sterilized cream;

- fermented cream products: fermented cream and fermented cream with yoghurt culture;

- other types of cream

HEAT-TREATED CREAM

- placed on the market as pasteurized or sterilized cream.

- in production and on the market, it must meet the following requirements:

- to be white or white-yellow in colour;

- to have a characteristic aroma and a pleasantly sweet taste;

- that it is of homogeneous consistency

In the production of heat-treated cream, it is allowed to add additives, in accordance with the regulations governing additives

Cream for coffee and cooking

Cream for coffee and cooking has a lower milk fat content, usually 10-18%, and can usually be found on the market in smaller packages.

This cream is homogenized during production after mixing with skimmed milk in order to standardize it to the desired milk fat content. The homogenization pressure is 10 – 20 MPa, at a temperature of about 55°C. It is pasteurized at a temperature of 85-90°C, for 15 to 20 seconds, and then cooled abruptly to 5°C. If it is planned to be stored for a longer period of time, then it is sterilized and aseptically filled.

Coffee cream should be viscous, have good thermal stability and should not flocculate when added to hot coffee.

Whipped cream / sweet cream

Whipped cream or sweet cream is used to make/whip cream for various desserts. Whipped cream can be found on the market as a pasteurized or sterilized product. You can also find whipped frozen cream.

In addition to good taste, a good whipping property is also important, whereby foam is obtained with an increase in volume. A prerequisite for good whipping properties is a sufficient content of milk fat (min. 35%) and a high content of lecithin that develops quality foam. In the production process of whipping cream, mixing with air that damages the finished product must be avoided.

Before the whipping of the cream, it must stand at a temperature of 1 to 4°C, for about 24 hours, in order for the cream to mature physically, which is a precondition for having the cream whipped properly.

FERMENTED CREAM PRODUCTS

Fermented products can be obtained from cream, as well as from milk, by adding starter cultures. These products differ according to the content of milk fat and depending on the added starter culture, i.e., on the species and strain of microorganisms used in the fermentation process. On the Serbian market, there is usually fermented cream with a fat content of 20%, and yogurt culture (Lb.delbrueckii subsp. Bulgaricus, S. thermophilus) is used as a starter culture. Cream with a lower or higher milk fat content is less common (12%, 25%, 30%), and the so-called Lactococcus lactis is also less commonly used for the production of fermented cream (Lactococcus lactis subsp. lactis, Lactococcus lactis subsp. cremoris, citrate positive lactococci Leuconostoc mesenteroides subsp. cremoris).

Fermented cream has a solid homogeneous consistency, has a pleasant lactic acid taste, which depends on the starter culture used. The cream obtained by fermentation with the use of yogurt culture is more acidic, with a less pronounced aroma than the cream obtained by fermentation using mesophilic lactic acid bacteria, i.e., by applying Lactococcus lactis. It is often used as a spread or for cooking.

A high degree of hygiene is very important for good product quality. The most common defect in fermented cream is the development of yeast and mildew on the surface.

The Rulebook defines the basic characteristics that fermented cream must meet:

- to be white or white-yellow in colour

- to have a characteristic aroma and slightly sour taste

- it is of solid, homogeneous or uniform thick liquid consistency

- that the pH value is not less than 3.8

as well as the name under which they are placed on the market, depending on the type of applied starter culture:

- fermented cream – if the fermentation of cream is performed by adding a butter culture, which includes Lactococcus lactis subsp. lactis, Lactococcus lactis subsp. cremoris, citrate of positive lactococcus Leuconostoc mesenteroides subsp. cremoris

- fermented cream with yogurt culture – if the fermentation of cream is performed using lactic acid bacteria Lb.delbrueckii subsp. bulgaricus, S. thermophilus

- other fermented cream – if the fermentation of cream is performed using different types of lactic acid bacteria.

Fermented cream must contain live cells of lactic acid bacteria, unless it is heat-treated. If the fermented cream is heat-treated, it must be marked “heat-treated”.

Production of fermented cream

The first step in the production of fermented cream is separation, i.e., extraction of cream and standardization to the desired milk fat content. The further process of fermented cream production is similar to the production of fermented milk/soured milk. The basic steps in the production process are:

- Separation and standardization of cream,

- Homogenization,

- Heat treatment,

- Cooling to incubation temperature,

- Adding a starter culture,

- Filling into packaging,

- Incubation / fermentation (40-42°C or 20 -22°C)

- Cooling (1 – 8°C)

1. Separation and standardization

Separation of cream – by a separator. Due to the difference in density, under the action of centrifugal force, cream and skim milk are separated.

Standardization of milk fat content – Appropriate milk fat content in cream after separation is obtained by mixing cream and skim milk. There are different methods for calculating the quantities of products with different milk fat content that must be mixed in order to obtain a given final milk fat content.

2. Homogenization

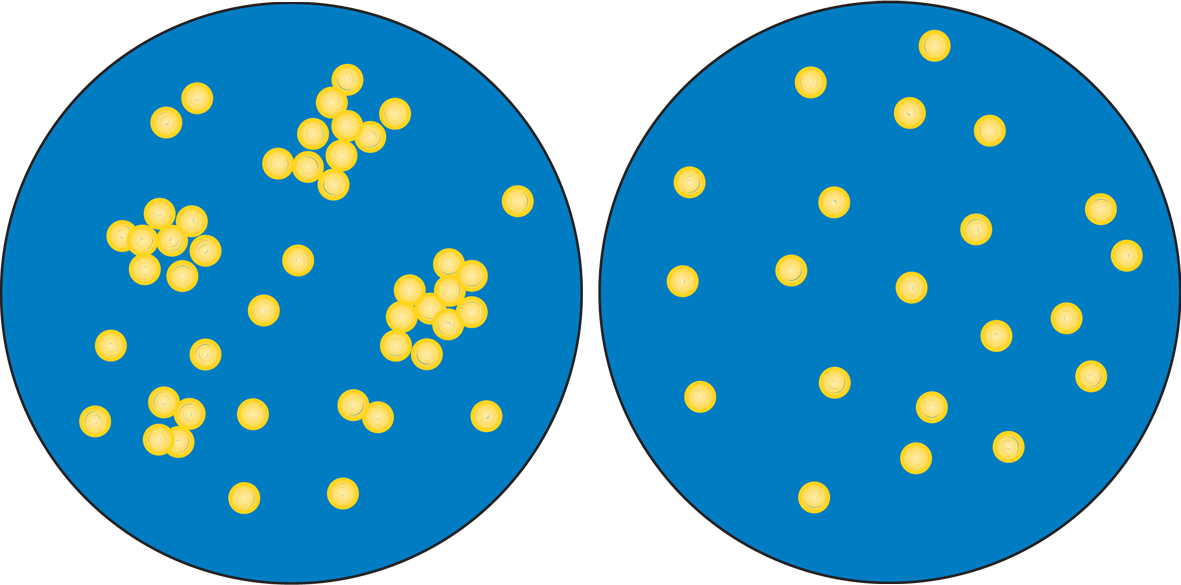

Homogenization is a standard industrial process, which aims to stabilize the fat emulsion. The homogenization process causes the fat globules to split into much smaller units, thus reducing the separation of cream, as well as the tendency to clump or coalesce. The result is a reduction in the diameter of the fat globules.

Homogenization pressure 150 -200 bar, at 55 – 60°C, for cream with 10 – 12% milk fat. Homogenization pressure 100 -120 bar, at 55 – 60°C, for cream with 20 – 30% milk fat (because there is not enough protein-casein, for the formation of membranes on the total increased surface area of fat). (See Homogenization)

3. Heat treatment

The homogenized cream is heat treated at 90°C for 5 minutes. Other appropriate combinations of time and temperature may be used. (See Pasteurization)

4. Cool to incubation temperature.

If thermophilic microorganisms – yoghurt cultures are used, cream is cooled to a temperature of 40-42°C. When using butter culture – mesophilic microorganisms, cream should be cooled to a slightly lower temperature of 20 -22°C.

5. Add starter culture with stirring.

If an active starter culture is used, about 2 to 2.5% is added. It is recommended to use lyophilized deep-frozen cultures which are added according to the manufacturer’s recommendation.

6. Filling into packaging.

Before the fermentation process, cream is filled into appropriate packaging, most often plastic cups or glass containers, which are closed immediately after filling. After the filling, the cream is transferred to the thermal chambers where the fermentation process takes place at the appropriate temperature.

7. Fermentation.

Fermentation is stopped when the acidity of the cream drops to pH = 4.5, and then the further lowering of the pH value is stopped by cooling. The length and temperature of cream fermentation depend on the starter culture used. When using yogurt culture, the fermentation time is shorter (4-6 hours), but at a higher temperature, 40-42°C. If a butter culture is used, the fermentation lasts longer (18 – 20 hours), at a lower temperature, 20 -22°C.

8. Cooling (1 – 8°C)

In order to stop the activity of microorganisms and prevent a further drop in pH, i.e., the increase in acidity, the cream is cooled. When transferring cream from the fermentation chamber to the refrigerator, care should be taken to transfer the cups carefully, so as not to disturb the structure of the fermented cream. The cream is stored at least 24 hours before distribution on the market.

Post-assesment

Seperation of milk fat

Presentation – Seperation of milk fat

Downloads

Milk fat is the most valuable and at the same time the most expensive ingredient in milk. Apart from milk, people tried to use products in their diet that to a greater or lesser extent contain certain milk ingredients. Milk is an emulsion or suspension of milk fat in water containing a number of substances in solution (lactose, minerals, vitamins, …), as well as ingredients in a colloidal state (proteins). Milk fat in milk is found in the form of small globules and has a lower density than other milk ingredients, it is separated on the surface of milk during standing or by a separator. The most common products obtained by concentrating milk fat are: cream, kaymak, butter and ghee.

Natural separation of fat from milk

- Milk fat (920 kg/m3) has a lower density than skimmed milk (1030 kg/m3) and when milk is standing, it is released on the surface. Separation speed depends on:

- The size of fat globules, the separation rate increases with increasing the diameter of the fat globule,

- Differences in the density of skimmed milk and fat, the separation rate increases with increasing difference in density and

- The viscosity of skimmed milk, the separation rate decreases with increasing the viscosity of skimmed milk.

The property of separating milk fat on the surface of milk has been used to separate cream. After milking, the milk was poured into containers that were placed in cold water or left in cold air, and after 12 to 24 hours, the cream was removed from the surface.

This method is slow and impractical for modern industrial production, where milk fat is separated by a separator.

Separation of milk fat using a separator

Separators are devices that separate milk fat from milk. By separating the milk, the skimmed milk is separated from the milk fat. The separation is based on the difference in the density of milk fat and skimmed milk, with the application of centrifugal force. The centrifugal force acts much stronger than gravity, so using a separator makes the separation of milk fat much faster.

Types of separators

Separators used in the dairy industry can be classified based on several criteria, and the basic classifications are according to their purpose, construction and power.

- According to the purpose in the dairy industry, there are:

- Separators for skimming and partial purification of milk, whey, etc.

- Clarifiers for milk purification, and

- Bactofuge for removing bacteria from milk.

- According to the construction, there are:

- Open separators, with open milk in-flow and open out-flow of skimmed milk and cream,

- Semi-closed separators, with open milk in-flow and closed out-flow of milk and cream,

- Hermetically sealed separators, where the milk in-flow is hermetically sealed, as well as the out-flow of skimmed milk and cream.

Figure 1. Separators of different construction

Figure 2. Closed, self-cleaning separator

- According to the power:

- Manual

- Mechanical (electric motor, pulley or steam turbine)

- Combined (manual and mechanical).

Figure 3. Manual separator

The principle of operation of the separator

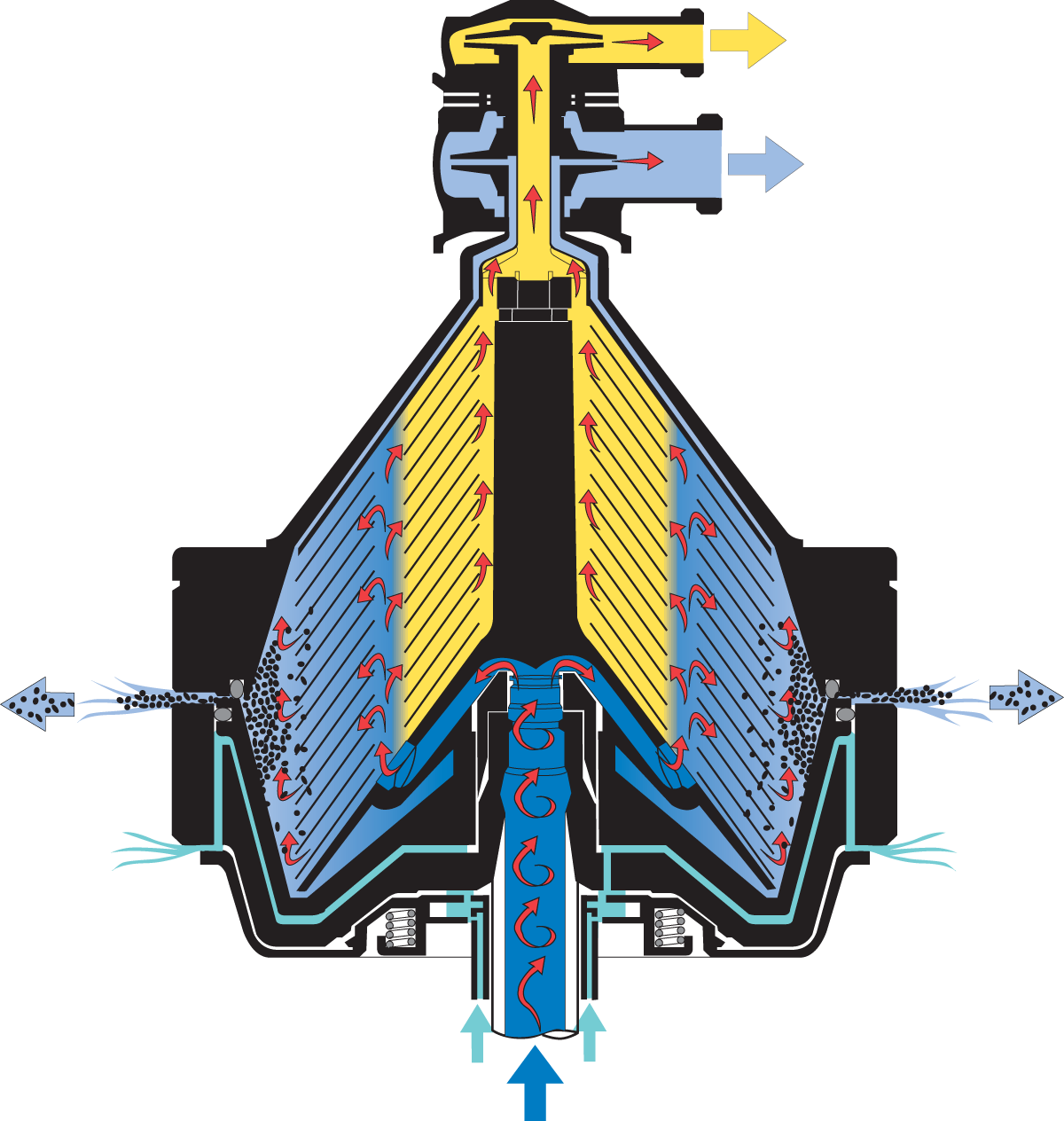

The separator for milk skimming is usually located in the pasteurization line, from where milk, after preheating in the pasteurizer, passes into the separator where the cream is collected. The milk is released into the separator only when it reaches the prescribed number of revolutions (6,000-7,000 rpm). During operation, the separator drum is continuously filled with milk, which is distributed through the openings in layers between the discs during rotation. There are 120 discs in the separator drum, which are placed one above the other, at an angle of 45° (Figure 4). Fat globules, as specifically lighter, move towards the axis of rotation, and skimmed milk, as specifically heavier, moves towards the perimeter of the separator drum. Milk fat is drained in the form of cream through the opening for cream, and skimmed milk through the opening for skimmed milk (Figures 5 and 6). The smallest fat globules do not have time to settle, so they go away together with skimmed milk (about 0.05% milk fat).

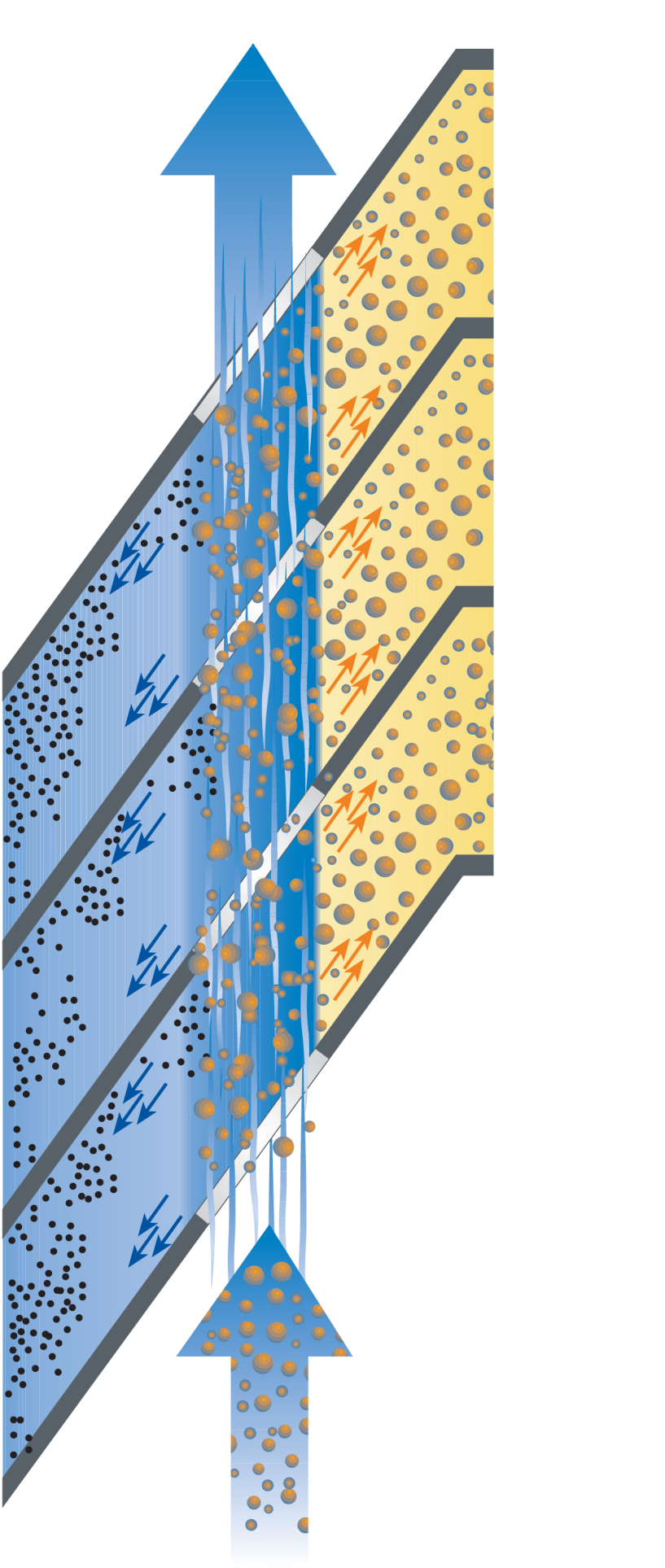

Figure 4. Disc stack with distribution holes and caulks (Dairy Processing Handbook ©Tetra Pak)

Figure 5. Schematic representation of how the separator works(Dairy Processing Handbook ©Tetra Pak)

Figure 6. Sectional view of part of the disc stack, showing the milk entering through the distribution holes, and separation of fat globules from the skim milk (Dairy Processing Handbook ©Tetra Pak)

During operation, dirt accumulates in the separator drum, so the separator must be stopped, opened and cleaned. New types of separators so-called self-cleaning separators, remove dirt automatically during operation.

Figure 7. Separation of dirt particles in self-cleaning separators

(Dairy Processing Handbook ©Tetra Pak)

The efficiency of milk skimming is influenced by a number of factors:

- Separator type (diameter and speed of rotation), with the increase of the diameter of the separator, the performance increases, and with the increase of the number of revolutions of the drum, the centrifugal force and the separation of fat from the milk increase.

- Temperature of milk to be skimmed. In industrial milk processing, skimming is most often performed at a temperature of 40-45°C. Cold skimming leaves 0.15 to 0.30% of milk fat in skimmed milk, and skimming at temperatures above 60°C increases the corrosion of the separator, and the viscosity of milk increases due to albumin coagulation and thus reduces the efficiency of skimming.

- Diameter of fat globules. Small globules of milk fat (less than 1×10-6m) move more slowly and are unlikely to separate.

- Product viscosity. As the viscosity of the milk increases, the separation of fat globules decreases, and thus the effect of the separator decreases. Heated milk has a lower viscosity than cold milk, so heating milk improves separation. Also, milk with an increased degree of acidity, i.e., with a lower pH value, due to the increased viscosity, will be less skimmed.

STANDARDIZATION OF MILK FAT CONTENT

Raw cow’s milk contains an average of 3% to 4.0% of milk fat. In the production of different dairy products, it is necessary to standardize the milk fat content in order to achieve a uniform content in the final product. Standardization of milk fat content is the process of adjusting the milk fat content in milk intended for the production of various dairy products. Standardization can be achieved by using a separator or by mixing skimmed milk and milk/cream. The standardization process yields milk with the required milk fat content.

Strategic planning

Scheme 1. Milk separation and standardisation process (Dairy Processing Handbook ©Tetra Pak)

Kaymak

Presentation – Kaymak

Video – Kaymak homemade

Video – Kaymak large scale

Downloads

Pre-assesment

Kaymak is a unique dairy product with a specific way of production, taste, aroma and texture, so as such it belongs to delicatessen and exclusive dairy products. It is a traditional dairy product that is obtained by removing the fat layer or crust from the surface of boiled and cooled milk, after the milk has stood in a shallow container (wooden vessel) for 1 to 4 days. According to its sensory properties, kaymak is between cheese and butter. During ripening, the aroma of kaymak changes from an aroma that is similar to butter to the aroma of semi-hard/hard cheese, while the changes in consistency (structure) range from cheese to butter.

In Serbia, the production and consumption of kaymak has a very long tradition, so this product is considered a domestic indigenous product and is one of the symbols of our gastronomy. It is most often produced from cow’s milk and is used for direct consumption. It is consumed as a side dish in cold appetizers, and then in grilled dishes and other main dishes.

In addition to Serbia, kaymak is also produced in other Balkan countries (Montenegro, Bosnia and Herzegovina, Macedonia and Croatia), but it is known by another name. The production of kaymak and similar products is also present in the countries of Southeast Europe, Asia Minor and the Middle East. There is a product similar to our fresh kaymak in England called “Devonshire cream”.

It is assumed that the production of kaymak started in Asia (the Iranian plateau and the central part of Asia). Nomadic cattle breeders who came from northern Europe and the southern part of Asia brought with them the technology of kaymak production to the Balkan Peninsula.

Today, kaymak is mainly produced in rural households and small dairies in the traditional way. Small farms produce kaymak and lean cheese (from milk after removing the kaymak) for their own needs, and bring the surplus to the market.

In our region, kaymak is most often produced from cow’s milk, and it is also the highest quality kaymak and is used for direct consumption. Kaymak made from sheep’s milk is often further processed into butterfat.

Depending on whether the kaymak is consumed immediately after removal or stands for a while and “ripens”, there is a difference between “fresh” kaymak with a shelf-life of 1 to 2 weeks and “matured” kaymak with a shelf-life of 1 to 6 months.

The chemical composition of kaymak varies a lot depending on the composition of the raw material and the method of preparation. In addition to milk fat, which is the main ingredient in kaymak, it also contains significant amounts of protein, minerals (especially salts), lactic acid and lactose. When milk of good standard quality is used and when the production process is properly performed in good hygienic conditions, kaymak of good quality and standard composition is obtained.

Legal regulation

The Rulebook on the quality of dairy products and starter cultures (Official Gazette of RS, 33/2010, 69/2010, 43/2013 – other rulebook and 34/2014) provides a definition of kaymak and defines the basic parameters that kaymak must meet.

Fresh kaymak or clotted cream is a product obtained as a fat layer or crust, which is separated from heat-treated and cooled milk (cow’s, sheep’s and buffalo’s milk or a mixture), where the following quality requirements must be met:

- to be white to light yellow in colour;

- to have a characteristic pleasant aroma and mild taste;

- to contain not less than 65% of milk fat in dry matter;

- to contain not less than 60% of dry matter;

- to contain not more than 2% of table salt;

- that the pH is not less than 4.8;

- that it is a layered structure with pieces of soft undrained matter.

The taste and aroma of fresh kaymak is mild, typically milky, reminiscent of boiled milk and cream, it tastes more like butter than cheese.

Fresh kaymak has a filo-like, layered structure with parts of undrained crust. The structure of fresh kaymak is similar to the structure of some fresh cottage cheese, but it is softer and more easily spread. The colour of the fresh kaymak is extremely light (ivory to pale yellow), which depends on the type of milk from which it is produced.

The shelf-life of fresh kaymak is up to 50 days, which depends on the storage conditions and the type of packaging.

Ripen kaymak or clotted cream is a product obtained as a fatty layer or crust, which is separated from heat-treated and cooled milk (cow’s, sheep’s and buffalo’s milk or their milk mixture), where the following quality requirements must be met:

- that it is light yellow to yellow in colour;

- to have a pronounced characteristic aroma and taste of matured kaymak or clotted cream;

- to contain not less than 75% of milk fat in dry matter;

- to contain not less than 65% of dry matter;

- to contain no more than 3.5% of table salt;

- that the pH is not less than 3.8;

- that the structure is granular or layered and that it spreads well.

Ripen kaymak has a pronounced and specific taste and aroma. During the ripening process, lipolytic changes occur, which lead to the formation of a large number of volatile compounds, which contribute to the formation of a sharp and very intense taste and aroma of ripen kaymak. The aroma of matripenured kaymak is reminiscent of some ripen hard cheese with a long ripening period. In addition to lipolytic, there are also proteolytic changes that also contribute to the formation of specific sensory characteristics.

Ripen kaymak has a typical granular structure and has a higher spread-capacity compared to fresh kaymak. The granular structure of ripen kaymak is the result of complex changes that occur during ripening that bring to disruption of the continuity of the protein phase, with the fat phase taking over the dominant basis of the structure. The structure of ripen kaymak is more similar to the structure of butter.

The shelf-life depends on the ripening process and if done correctly can be up to six months.

Technological bases of kaymak production process

The production of kaymak is based on the surface activity of boiled milk, on the surface of which an initial crust is formed after heating and pouring the milk into open shallow containers.

After boiling the milk, a “crust” is formed on the surface of the milk. The process of formation of the “crust” on the surface of milk is closely related to the physical properties of certain components of milk, especially fats and proteins. When boiling the milk, there is a partial denaturation of milk proteins and a concentration of hardened proteins around which other milk ingredients, primarily milk fat, begin to accumulate. Milk fat globules tend to cluster. Larger globules of milk fat are the first to overcome the viscosity of milk and move towards the surface. On their way, they catch up with smaller globules, and they group into agglomerates and separate on the surface of milk. Milk fat, as the lightest ingredient in milk, tends to stand out on the surface of milk. Fat globules have a membrane to which proteins are bound, and they also contain clotted proteins, so that a product is obtained which is a mixture of fat and protein (smaller share).

The speed of kaymak separation depends on various factors, and the most important are: milk temperature, humidity and air temperature, as well as the temperature difference between milk and air.

The amount of separated kaymak that is formed is proportional to the milk fat and the surface of the milk spill, and inversely proportional to the height of the spilled milk layer, the rate of the temperature drop, and the heat conductivity of the vessel in which the kaymak layer is separated.

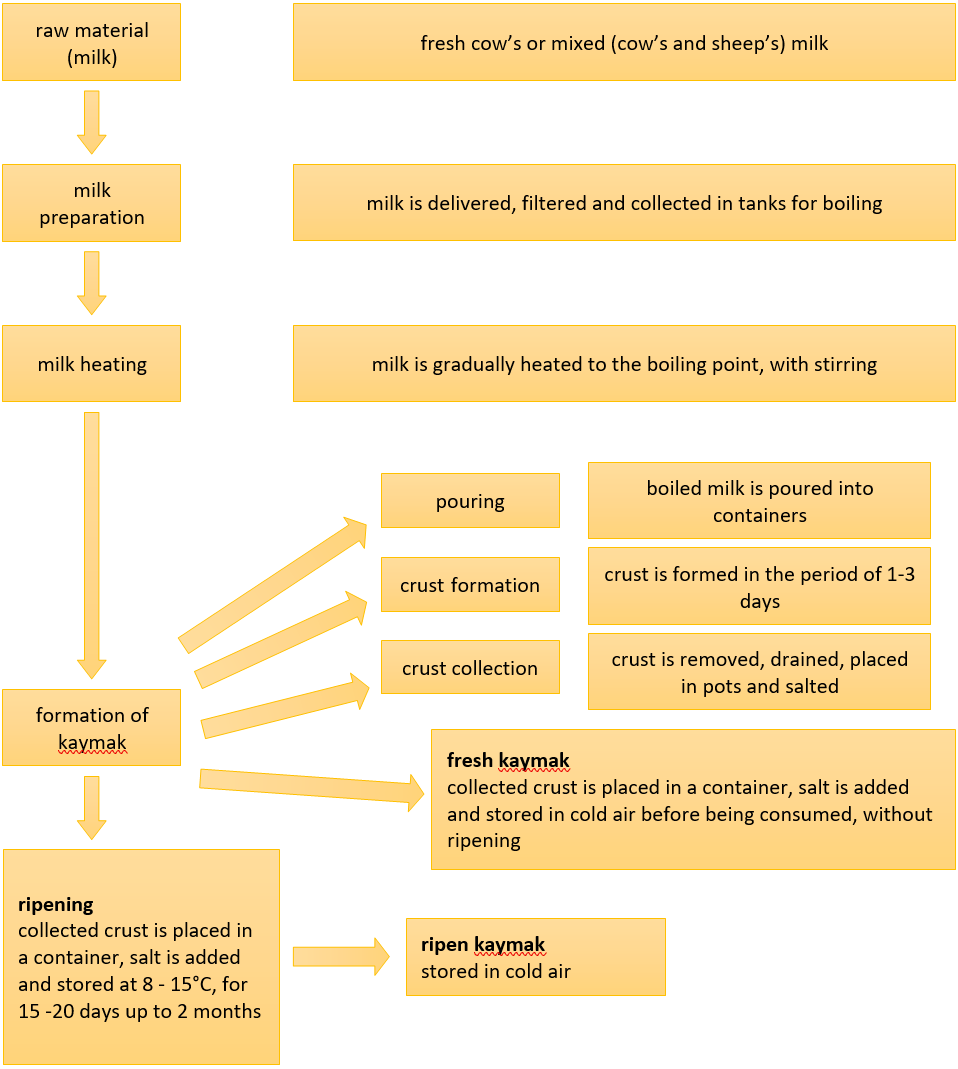

Kaymak making

There are the following steps in the process of kaymak making:

- Milk selection – whole, non-homogenized milk is used. Cow’s milk is most often used.

- Pasteurization – milk boiling. Kaymak is produced exclusively from boiled milk, which boils for 5 to 10 minutes.

- Pouring boiled milk – after boiling, milk is poured into shallow containers, once wooden vessels, and today enamelled dishes or stainless-steel containers. The milk stays in the containers until the kaymak is removed. In some households, milk is boiled and left to form kaymak in the same containers – shallow pots.

- Kaymak formation – formation of a crust on the surface of milk and separation of milk fat. It is desirable to cool the milk slowly. The milk stays in the container for 1 to 3 days (especially in the winter months).

- Removing the kaymak – At the moment of removing the kaymak, it is desirable that the milk is cold 10-15°C, because then the layer of fat under the crust is removed with the kaymak. If the temperature of the milk at the time of removing the kaymak is over 20°C, the layer of fat does not harden and remains in the milk. Before removing, the knife is passed between the kaymak and the wall of the container, so that the cream can be grasped more easily. The kaymak is removed with a perforated spoon or by hand. After removing the kaymak, it is placed in containers to ripe (if ripen kaymak is produced) or fresh kaymak is stored. In the past, wooden pots were used, and today plastic pots of different shapes and sizes are used.

- Adding salt – Before placing the kaymak on the bottom of the pot, a little salt is added, and salt is also added over each layer of kaymak. The amount of added salt depends on the length of storage of the kaymak. When making ripen kaymak it is necessary to add more salt, because salt not only affects the taste, but also has the role of a preservative.

- Ripening and storage of kaymak – Containers with kaymak during the ripening time are kept in a room with a basement temperature of 10 – 15°C. Ripening lasts 15 to 20 days and kaymak can be stored for a long time (up to 6 months) in the cold. The surface of the ripen kaymak, which is stored longer, is covered with melted butterfat.

Scheme 1. Block scheme of kaymak making

Yield

The yield in the production of kaymak is very uneven, because the production process is influenced by a number of factors. The chemical composition and quality of milk have a primary influence, especially the milk fat content and total dry matter. The technological process of work is also important, such as the way and duration of heating and boiling of milk, the kaymak formation process, the temperature of the room in which the kaymak formation process takes place, the speed of fat separation, and the way of removing the crust from the milk.

After removing the kaymak from the total amount of milk, 81 to 90% of skim milk remains. To produce 1 kg of fresh kaymak, it is necessary to use 8 to 15 litres of cow’s milk.

Chemical composition of kaymak

Apart from large differences in yield, there are also large variations in terms of the chemical composition of kaymak, but the values are mostly within the limits prescribed by the regulations.

Sensory properties of kaymak

Kaymak as a specific dairy product is characterized by characteristic sensory properties. The sensory properties of kaymak are often similar to certain properties of cheese or butter, but still very specific.

Colour – depends on the degree of maturity of the product and the chemical composition of milk fat. Fresh kaymak is of a light, whitish colour to the colour of ivory. In relation to butter, the colour is lighter, but it is more intense in relation to the colour of fresh cottage cheese that is completely white. Ripen kaymak, as well as ripen cheese, has a distinct yellow colour.

Aroma – the taste and smell of fresh kaymak are not particularly pronounced. It has a typical mild milky taste, similar to the taste of boiled milk and tastes more like butter than cheese. Intense taste and smell of ripen kaymak is formed during the ripening period. Lipolytic changes produce a large number of volatile compounds that contribute to the formation of a sharp and rather intense aroma. The aroma and taste of ripen kaymak are reminiscent of cheese with a long ripening period. During the ripening period, the aroma of the kaymak changes from butter-like to cheese-like.

Kaymak structure – there are big differences in structure and consistency between fresh and ripen kaymak. Fresh kaymak has a spread consistency and is layered. Ripen kaymak has a recognizable granular structure, which is formed as a consequence of the ripening process, so that the structure of the kaymak during the ripening period reaches the structure of butter.

Kaymak packaging

Traditionally, kaymak was removed and placed in wooden tubs and stored in them. Today there are a number of modern packaging materials and packaging methods.

Appropriate packaging should ensure the preservation of quality, standard weight, hygienic conditions of storage of kaymak.

The packaging process itself, as the last in the process of kaymak production, gives the final look of kaymak, both fresh and ripen. When packing ripen kaymak, care should be taken that there is no air between the layers.

Packaged kaymak is stored at a temperature of +4°C to +8°C. If the kaymak is stored at higher temperatures, there is an increase in acidity.

Traditional method of kaymak making

This method of kaymak making is very simple and is quite common on farms where milk is produced.

Procedure:

Whole fresh milk is gradually heated to boiling (Figure 1). It is important to heat the milk gradually to avoid the smell of “burnt” milk with kaymak. Some households add up to 10% of water to the milk before heating to avoid the smell of “burnt milk”. Gradual heating is also important due to better milk boiling, which affects the better quality of the finished product. The milk is stirred occasionally during heating. It can be boiled in suitable pots and then transferred to pots for kaymak formation or boiled in pots in which the kaymak is then left to separate.

Traditionally, after boiling the milk, the milk was poured into wooden containers, where the kaymak stood out (Figure 2). Kaymak formation containers should have a larger diameter of about 50 cm, and a height of about 12 to 15 cm, with an extended upper surface. This shape of the dish is recommended for better kaymak formation, i.e., separation of fat globules, proteins and other kaymak ingredients. When pouring the milk, the formation of foam should be avoided, because it adversely affects the formation of the crust and the kaymak formation itself.

Figure 1. Traditional method of milk heating on a wood burning stove

Figure 2. Wooden containers for milk pouring and a pot for kaymak storage

After the formation of the initial crust, the process of slow cooling to a temperature of about 15-18°C begins, i.e., in some areas at about 10-15°C for 12-24 hours. In addition to the room temperature, for the good separation of milk fat and the creation of kaymak, the type of material from which the dishes are made is important. Today, enamelled or stainless-steel dishes are mostly used, and less often wooden or plastic ones. Enamelled and stainless-steel dishes make it easier to maintain hygiene, while wooden dishes better maintain the temperature of the milk after kaymak formation. It is undesirable to use plastic utensils, which retain heat poorly and negatively affect the quality (taste and aroma) of the finished product.

The duration of milk cooling significantly affects the thickness of the separated crust. Kaymak formation lasts from 12 hours to 3 days, which mostly depends on the weather conditions and the room temperature. It separates fat and incorporates it into the already formed layer of the protein, forming a thin layer.

In some areas, the kaymak formation takes 24 hours, at a temperature of 4-6°C. The relatively short period of kaymak formation causes a higher content of milk fat to remain in the milk, and such milk is used for the production of semi-fat cheese. Lower temperatures and short kaymak formation time also prevent more intensive development of milk acidity before using it for cheese making.

The amount of kaymak that is formed in a certain period of time is proportional to the content of milk fat in the milk and the surface of the spilled milk, and inversely proportional to the height of the milk layer and the rate of temperature drop.

It is very important to determine the right time to remove the kaymak. If it is removed early, not all the fat from the milk is separated and the yield of kaymak is reduced. If the kaymak is removed late, it happens that the milk turns sour and with the removal of the kaymak, sour milk is picked up as well, which negatively affects the quality of the kaymak. The experience of the person in charge of kaymak production plays an important role in assessing the right time to remove the kaymak.

The formed kaymak is removed from the surface of the milk and placed in a bowl to drain part of the collected milk (1 to 2 hours). This phase lasts a short time, and then the kaymak is layered and salted in appropriate containers. At the bottom of the tub (a wooden container in which the kaymak is placed) there is an opening through which the remaining milk flows out and thus the moisture content in the kaymak is regulated. If it is not drained enough, the stratification is lost and the acidity increases, and the excess moisture negatively affects the quality of the product.

The kaymak is collected every day until the bowl is full. The time of filling the tub is also a very important factor for the quality of the kaymak. The shorter the filling time, the more evenly the kaymak ripens, and the better quality and sensory properties are obtained. In some areas, after the filling is completed, the tub is loaded with a wooden circle and a stone. The whey that pours out stands out on the surface, and the kaymak is stored only under the load. This is done to create anaerobic conditions for ripening.

Fresh kaymak is consumed directly after the production or in the next couple of days (Figure 3).

Ripen kaymak reaches full maturity after ripening from 15 – 20 days to two months at a temperature of 8 – 15°C (Figure 4). Ripen kaymak can be stored for up to a year, if all technological procedures are followed and if it is stored at appropriate lower temperatures.

Figure 3. Fresh kaymak

Figure 4. Ripen kaymak

Kaymak making in small dairies

Kaymak making in small dairies is a combination of traditional and industrial way of production. The kaymak making in small dairies takes place using modern equipment and in improved working conditions. Duplicators are used for milk heating, in which better and more correct heating and cooking of milk is provided, which later has a positive effect on the separation of the crust. Departments for kaymak formation and maturity should be separate, because different conditions must be provided in terms of temperature, humidity …

Procedure:

Raw milk is heated in a duplicator to the boiling point. At the end of heating, the milk can be stirred to prolong the boiling. The duration of milk boiling depends on the amount of milk, the type of dishes and sources, or the energy used in boiling.

Once the milk is boiled, it is poured into appropriate containers for kaymak formation (separating the fatty crust) and transferred to the kaymak chamber. The milk is poured into kaymak containers with a volume of 30 to 40 l, which are arranged in several levels on racks (usually there are 5 levels on the stand) for the kaymak making. The stand is on wheels and thus, after spilling and partial cooling, it is transported to the cooling chamber (Figure 5).

Figure 5. Cooling chamber with kaymak containers on the racks

The process of kaymak making, i.e., separating fat and creating crust, is quite slow. Therefore, it is necessary to cool the spilled milk gradually and to maintain the favourable temperature of the milk and the room in which the kaymak is kept for as long as possible. The most favourable temperature of the room in which the kaymak formation takes place is 15 – 18ºC.

After a couple of hours, it is necessary to gradually lower the temperature, so that immediately before collecting the kaymak, the temperature is 4ºC.

The crust is removed from the milk after the kaymak formation. After removing it, the crust is placed in containers and kept in them for a couple of hours, in order to separate a part of the collected milk. The crust is then layered into larger containers and salted (Figure 6). The amount of salt added usually ranges up to 2%.

The final packaging of the kaymak is done manually, in plastic containers and thus delivered to the market.

Figure 6. Kaymak layered in plastic containers

Figure 7. Kaymak container measuring

Post-assesment

Homogenization

Presentation – Homogenization

Downloads

Pre-assesment

Homogenization is a standard industrial process which aims to reduce and even out the diameter of fat globules in milk and cream, by applying high pressure. The aim of homogenization is to increase the stability of the milk fat emulsion, i.e., to prevent the separation of fat on the surface of the milk during standing still.

Homogenization breaks down fat globules, which diameter in cow’s milk varies from 1-5µm (0.1 – 22µm), and usually ranges from 3-4µm (see Milk fat module). One of the most important differences between goat’s and cow’s milk is in the structure and composition of milk fat. The average size of fat globules in goat’s milk is 2 µm, so it is often said that goat’s milk is naturally homogenized.

In the usual homogenization process, fat globules with a diameter of less than 2 µm are formed, and the number of globules can be increased up to 100 times, and the total surface area of the globules up to 6 to 10 times. Thanks to homogenization, the separation of milk fat/cream on the milk surface is reduced.

The homogenization process is applied in the production of drinking milk (pasteurized and sterilized), where in addition to preventing the separation of milk fat on the surface, homogenized milk gets a fuller and richer taste, as well as increased viscosity. In the production of fermented dairy products, in addition to increasing the stability of milk fat, homogenization also achieves a more difficult separation of milk serum due to the higher hydration of homogenized fat globules.

Homogenization is not recommended for milk intended for the production of cheese, especially semi-hard and hard cheese, because it leads to a violation of the technological properties of milk. Also, cream for butter production is not homogenized.

Homogenization process

Milk homogenization is usually performed at a temperature of 50 – 60°C and a pressure of 150 – 200 bar (15-20 MPa). The homogenizer must be placed so that heated milk gets into it, i.e., the milk fat is in a liquid state. It is most often placed in the line of milk pasteurization, i.e., the milk after preheating and separation/standardization goes to homogenization, and then returns to the pasteurizer for heating to the pasteurization temperature. In addition to homogenizing the entire amount of milk, partial homogenization can also be performed, when only the cream or part of the cream is homogenized after leaving the separator, and then the homogenized cream is mixed with skimmed milk and pasteurized (Figure 1).

Figure 1. Product flow at partial stream homogenization (Dairy Processing Handbook ©Tetra Pak)

Homogenization can be one-stage or two-stage homogenization. In two-stage homogenization, the pressure is higher in the first stage and amounts to 15-25 MPa, and in the second stage it is lower, 5 – 10 MPa. The second stage prevents the reunion of fat globules and provides controlled and constant pressure after the first stage of homogenization and thus maximum efficiency is achieved.

Figure 2. Disruption of fat globules in first and second stages of homogenization (Dairy Processing Handbook ©Tetra Pak)

The figure shows the appearance of fat globules in raw milk, cold raw milk, and homogenized milk during the storage.

Figure 3. Appearance of fat globules in raw, cold and homogenized milk

Homogenizer

The first homogenizer was patented in 1899 by August Gaulin in France. First, consumer pasteurized milk was homogenized in order to prevent the separation of the layer of milk fat – cream on the surface of the milk during standing. The construction of each homogenizer consists of several high-pressure piston pumps and a homogenizer valve system. The main part in the homogenizer is the homogenization head with valves, which can be of different constructions. Non-homogenized milk passes through small valve openings and then fat globules are reduced in size (Figure 4).

Figure 4. Homogenization valve (Dairy Processing Handbook ©Tetra Pak)

When entering the valve gap, the pressure energy is converted into velocity energy. After a thousandth of a second at the valve outlet, there is again a large change of velocity into pressure, which causes turbulence. Due to this intensive mechanical treatment, first at the entrance to the narrow valve gap there is a deformation and stretching of the fat globule, and at the exit, the final splitting into smaller globules occurs. After splitting or comminution of fat globules, the fat globule membrane regenerates by adsorption of proteins from milk (Figure 5). Smaller fat globules contain more protein, especially casein, so homogenized milk is whiter. Even after homogenization, milk fat is in the form of fat globules, and not as free fat.

Figure 5. Appearance of fat globules before and after homogenization and distribution of casein micelles

Homogenization does not achieve absolute stability and does not prevent the movement of fat globules towards the surface (it just makes it much slower). That is why this milk is not called homogeneous but homogenized.

Homogenization Results

The main result of homogenization is obtaining a stable emulsion, which means that the size of the fat globule does not change significantly with time and with a significantly reduced tendency to move. Other advantages are:

- Smaller fat globules leading to less crem-line formation

- Whiter and more appetizing colour, even in products with reduced milk fat

- Reduced sensitivity to fat oxidation

- Better stability of cultured milk products

In addition to the advantages, the homogenization process can also cause certain disadvantages of milk, such as:

- Homogenized milk cannot be efficiently separated

- Increased sensitivity to light

- Increased tendency to lipolysis, due to the larger total surface area of milk fat globules

- Reduced thermal stability

- Reduced ability to coagulate casein, after the homogenisation process a part of the casein is used to regenerate the fat globule membranes

- Homogenized milk might be less suitable for production of semi-hard or hard cheeses because the coagulum will be too soft and difficult to dewater

Post-assesment

Butter

Presentation – Butter

Video – Butter homemade

Downloads

Pre-assesment

Butter is an energetically and nutritionally highly valuable dairy product, which is obtained by processing sweet or fermented (sour) cream, by the process of churning. During the process of churning, the fat globules unite and first smaller and then larger butter grains are formed, and buttermilk is separated. Butter is generally a concentrated milk fat and contains a minimum of 82% milk fat.

Whey butter made from cream obtained by whey separation can also be found on the market, as well as butter with additives.

Butter production has been known since ancient times. Butter was originally made on farms for domestic use. The milk fat separated naturally, as a surface layer of milk, and then it was removed and left to ripe naturally, and then it was churned. The churning was done in wooden manual churns. The traditional way of butter production is unacceptable today due to poor hygienic conditions that can result in poor quality and health safety of the finished product.

Figure 1. Manual churns for butter-making

The invention of the separator (1878) enabled the fast and efficient skimming of cream from milk, which enabled a great leap in the butter production, and the quality and economy of production were further increased by the introduction of the pasteurization process (1880). Modern butter production, with the application of controlled acidification, has resulted in a significant improvement in product quality.

Legal regulation

The Rulebook on the quality of milk products and starter cultures (2014) defines the requirements that butter must meet:

- To have a characteristic aroma, taste and colour;

- To have an easily spread, homogenous consistency without visible water droplets;

- To contain not less than 82% of milk fat;

- To contain no more than 16% of water, and

- To contain no more than 2% of dry matter of fat-free milk.

As well as the requirements that whey butter must meet:

- To have a characteristic smell, taste and colour;

- To have an easily spread, homogenous consistency without visible water droplets;

- To contain not less than 80% of milk fat;

- To contain no more than 18% of water, and

- To contain no more than 2% of dry matter of fat-free milk.

TECHNOLOGICAL PROCESS OF BUTTER-MAKING

The butter-making process includes the following stages

- Cream production – includes the process of milk skimming and standardization of milk fat content in cream

- Cream processing – means cream pasteurization, and then its physical and biochemical maturation – if butter is produced from fermented cream

- Processing of cream into butter – this is the process of churning when a butter grain is formed with the separation of buttermilk.

- Butter packaging, storage and distribution.

Butter can be produced by a batch and continuous process. The batch process is older and, in this process, butter can be produced from sweet and sour cream, and is usually applied in smaller dairies where there is also a smaller amount of cream. The continuous process of butter production is of a more recent date and it uses mainly sweet cream, and is used for the production of butter in larger dairies.

Figure 2. General process steps in batch and continuous production of cultured butter (Dairy Processing Handbook ©Tetra Pak)

- Milk reception

- Preheating and pasteurization of skim milk

- Fat separation

- Cream pasteurization

- Vacuum deaeration, when used

- Culture preparation, when used

- Cream ripening and souring, when used

- Temperature treatment

- Churning/working, batch

- Churning/working, continuous

- Buttermilk collection

- Butter silo with screw conveyor

- Packaging machines

CREAM PRODUCTION

Cream is an emulsion in which milk fat globules float in the water phase so-called cream serum. It is obtained by separating milk fat with a centrifugal separator or separating milk fat on the surface of milk during milk standing. The separation is performed at a milk temperature between 50 and 60°C, at that temperature all the milk fat is in liquid form, which is important for the success of the separation. After the separation, cream is standardized, usually up to 40% milk fat (by adding skimmed milk if the milk fat content is high, or by adding higher fat cream if the milk fat content is low).

To obtain quality butter, it is very important to choose cream of good microbiological quality, with taste and aromas.

CREAM PROCESSING

Before churning, it is necessary to pasteurize the cream, and then cool it to the ripening temperature.

Cream pasteurization

When processing the cream, care should be taken that cream for butter production is not homogenized. The cream is pasteurized at a temperature of 85-95°C, for 10 to 30 seconds. The goal of pasteurization is to destroy microorganisms, primarily pathogens, as well as their enzymes, and lipase inactivation is especially important.

Cream pasteurization shortens the churning time, which is a direct consequence of the changes that occur in milk fat and whey proteins.

Cream ripening

The cream ripening is a very important stage in the process of butter production. The taste and aroma depend on this phase, but also the consistency of the butter.

In cream ripening there are:

- biochemical and

- physical ripening

Biochemical cream ripening

Biochemical cream ripening is a process of fermentation of cream using mesophilic dairy cultures, the use of which produces sour/fermented cream. Mesophilic culture consists of selected strains of Lactococcus and Leuconostoc bacteria, which ferment lactose to lactic acid, but also produce citrates and aromatic substances – diacetyl and volatile acids. Biochemical ripening takes place at a temperature of 18-22°C, 12 to 20 hours, until the pH is lowered to 4.6. It is interrupted by lowering the temperature to below 10°C.

Physical cream ripening

Physical cream ripening implies physical changes in the structure of milk fat. Mandatory process in the production of butter from both sour and sweet cream, which comes before the churning. It takes place in duplicators at low temperatures, 10 – 12°C, lasting a maximum of 15 hours. The goal is to harden and crystallize the milk fat globules, which become more suitable for destabilization. There are also changes in the proteins attached to the membrane of the fat globule, which bursts more easily later in the process of churning.

The length of cooling depends on the composition of the fat, which depends on the season, i.e., the diet of the cows. In the summer months, when “green food – grazing” is present, milk fat contains fewer fatty acids with a lower melting point, and there is a high content of oleic acid, which results in a high iodine number and soft butter. The iodine number represents the number of g of iodine required to saturate unsaturated fatty acids in 100 g of fat and is an indicator of the proportion of unsaturated fatty acids. The optimal consistency of butter when the iodine number is 32 – 37. Due to all the above, the physical ripening of butter, at the same temperature, lasts longer in summer than in winter.

CREAM CHURNING

Cream churning is a process of agglomeration of fat globules, due to mechanical cream processing (which is an emulsion of fat in water) into butter (which is an emulsion of water in fat). In milk and cream, fat globules do not stick together because they are protected by a membrane. During the churning process, due to the rupture of the membrane of the fat globule, piles of fat globules are created, which are collected and connected into the butter grain. After the churning is completed, the buttermilk is released, which is a by-product in the butter production. Buttermilk contains about 8 – 8.5% dry matter, 0.3% fat, 3.3% protein, 3 – 3.6% lactose, 0.78% mineral matter and 0.1-0.12% lecithin.

BUTTER GRAIN RINSING

After releasing the buttermilk, the butter grain is washed with water, 2-3 times, but this is not an obligatory operation. The rinsing water must be bacteriologically and chemically correct, with the temperature that is by 1°C lower than the temperature of the butter. By rinsing, the remaining buttermilk is separated from the butter, i.e., proteins and lactose, in this way the shelf-life of the butter is extended, because the substances necessary for the growth and development of microorganisms are removed.

BUTTER WORKING AND SALTING

Working

The butter is worked to a homogeneous mass to regulate the amount of water in the butter. The working of the butter is done to obtain a homogeneous mass of butter, in order to obtain the smallest possible droplets of the aqueous phase, evenly distributed in the butter.

Salting

Salt can be added to the butter after rinsing, and before working. About 1.2 to 1.5% of salt is added in summer and 0.8 – 1% in winter. It gives taste and prolongs the shelf-life of butter.

BUTTER PACKAGING AND STORAGE

Butter is packed in packages (aluminium foil, paper, …) from 0.1 to 1 kg. Larger quantities of butter are packed in larger boxes of about 25 kg. When packaging, it is very important to avoid contact of the butter with air or light in order to avoid unwanted changes.

Butter is stored at temperatures of 4 – 5°C for a month. It can be frozen, so its shelf-life is significantly extended.

BATCH BUTTER-MAKING

Butter is produced by a batch process in churners. The churners are filled with cream up to 45% of the volume, because a lot of froth is created during the churning. The churning takes place at a temperature of 10-15°C (in summer at 8° -10°C, and in winter at 11° -14°C). The churner rotates at a speed of 20 to 30 rpm, during mechanical shocks the membrane of the fat globules cracks and butter grain is formed. The cream temperature rises to 2°C during the churning process. Churning lasts 35-45 minutes, and depending on the content of milk fat in the cream, the optimal content is 28-36%. Once the size of the butter grain gets 2 to 3 mm in diameter, the churning is finished. The length of the churning is also affected by the temperature, at higher temperatures it takes less time, but there is a higher percentage of milk fat in the buttermilk. After the churning is completed, the buttermilk is drained, the butter is washed and worked, and then it is packed and stored.

Figure 3. Low-capacity churner for small dairies

Figure 4. Churner

CONTINUOUS BUTTER-MAKING

The continuous butter-making process occurred as a consequence of efforts to shorten the duration of the butter-making process, reduce labour and energy costs. There are three different processes, and in Western Europe the most common is the Fritz process, developed from the batch butter-making process.

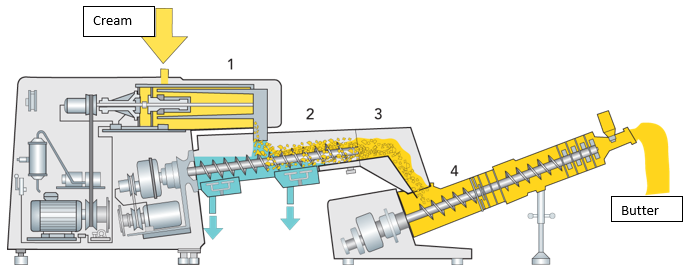

The cream from the ripening tank enters the first cylinder (1), which rotates at a speed of 2000 rpm, where a butter grain is formed, and in the second (2), which rotates 35 rpm, the buttermilk is separated. It then passes to the squeeze-drying section (3), in which the excess buttermilk is separated, and then to the second working section (4). The butter comes out in the form of a ribbon that is directed towards the moulding and packaging device.

Figure 5. A continuous butter-making machine (Dairy Processing Handbook ©Tetra Pak)

- Churning cylinder

- Separation section

- Squeeze-drying section

- Second working section

PRODUCTS SIMILAR TO BUTTER

Milk fat, from which water, proteins, lactose and other milk ingredients have been almost completely removed, is used in different parts of the world under different names, and different technologies are used in the production process.

In Serbia, this product is called maslo, in India ghee, in Arabia and Egypt samn, and in some eastern countries mislee. In European countries, the following names are used: butterfat, melted butter, liquid butter, etc., while in the USA it is called butter oil, and in Australia and New Zealand dry butterfat.

The use of dehydrated milk fat is especially present in warm tropical regions, with high temperatures, where the shelf-life of butter is reduced due to the faster development of microorganisms in the aqueous phase.

Butterfat

Butterfat is a dairy product with a high content of milk fat that is produced by melting butter or melting butter and cream. The butterfat is golden yellow in colour, with a pleasant taste and aroma.

Quality butterfat, in addition to a minimum of 98% milk fat, contains up to 1% water and up to 1% other ingredients. Shelf-life of butterfat with these characteristics can last longer.

The butterfat was mainly used in the household in which it was produced. It is popular in the diet of people from hot regions and people who do not use lard in their diet. Compared to butter, it is more stable at room temperature. It is suitable for reconstitution, both in obtaining milk from skimmed milk, and in the production of ice cream and chocolate milk.

Butterfat making

Most often, butterfat is produced by heating butter in a boiler/vessel to which a little water was added beforehand. While heating, the resulting foam is removed from the surface of the melted butter, and once the mass acquires a specific colour, the heating stops. The resulting butterfat is left to gradually cool and during cooling the precipitate, which consists of nitrogenous substances, lactose and minerals, falls to the bottom of the vessel. Once the temperature of the butterfat drops to about 35°C, it is poured, if necessary filtered, into clean containers and cooled at low temperatures.

In addition to the production of butterfat from butter, it can also be made from cream, when the churning process is avoided. Before heat treatment, it is necessary to break down the fat globules mechanically, in order to separate the fat.

The butterfat can be stored for up to a year at a temperature of 4°C.

GHEE

Ghee is a butterfat produced in India mostly from buffalo milk, which has a higher milk fat concentration (7.5%) and larger fat globule, compared to cow’s milk. It is obtained by sour cream churning and then melting the produced butter.

Ghee has a characteristic taste and smell that comes from the fermentation of the cream, and it also has a high concentration of free fatty acids. It is often darker in colour than butterfat, if the heating temperature exceeds 130°C. The structure depends on the method of cooling, with rapid cooling with stirring, a fine-grained structure is obtained, while with gradual cooling at room temperature without mixing, larger fat crystals are obtained.

ANHYDROUS MILK FAT – AM

A product that is concentrated milk fat and contains a minimum of 99.8% milk fat. It is made from cream or butter.

AMF is in the liquid phase at temperatures above 36°C and in the solid phase below 16°C.

AMF is an excellent form for storing and transporting fat, because it requires less space than butter and can be stored longer than butter (at a temperature of + 4°C butter can be stored for up to 6 weeks, and butterfat packed with inert gas may last for a few months).

AMF is suitable for use in the liquid phase. It is used in the industry for the production of chocolate and ice cream.

There are three different types of products, which are defined by FIL IDF International Standard 68A: 1977.

- Anhydrous milk fat – must contain at least 99.8% milk fat and is made from fresh cream or butter. The use of any additives is not allowed.

- Anhydrous butter oil – must contain at least 99.8% milk fat and is made from cream or butter of different maturation.

- Butter oil – must contain 99.3% milk fat, produced from cream or butter.

BUTTERMILK

Buttermilk is a by-product obtained in the butter-making. Buttermilk has a high concentration of fat globule membrane components, and therefore a high concentration of lecithin, about 0.5% milk fat. The shelf-life of buttermilk is very short due to the oxidation of the ingredients that make up the membrane. In the case of buttermilk obtained from fermented cream, whey is often separated.

The composition of buttermilk depends on the butter-making method. Table 1 shows the composition of buttermilk obtained after the butter-making from fermented and sweet cream.

Table 1. Chemical composition of buttermilk

| Composition (%) | Buttermilk from fermented cream | Buttermilk from sweet cream |

| Water | 91.5 – 92 | 91 |

| Fat | 0.3 | 0.5 |

| Proteins | 3.3 | 3.5 |

| Lactose | 3 – 3.6 | 4.4 |

| Ash | 0.78 | 0.73 |

| Lecithin | 0.1 – 0.12 | |

| Lactic acid | 0.6 – 0.7 | 0.01 |

Fermented buttermilk

In order to extend the shelf-life of buttermilk, fermented buttermilk is produced. Butter culture is most often used for fermentation, and skim milk can be added to improve the aroma and consistency.

The raw material is heat treated at a temperature of 90-95°C for 5 minutes, and the product is then cooled to the optimum temperature for the development of the added starter culture.

Post-assesment